Creo Detailed Drawing & Advanced Assembly: Level 2

Course Duration: 40 hours

Tuition: $2,300 USD

Overview: Participants in this Creo week-long course will learn in great detail both detail drawings with modern drawing standards, and Creo Advanced assembly functions. Participants have the option to customize this course to fit their specific job requirements, so they are able to learn exactly what they need. For example in a Design-Engine effort to cover advanced assemblies we may also present a serious introduction to Mechanism. Often we conduct an eight-hour effort on the topic of Creo Sheet metal. Participants’ choice. Call today and ask us how this, and other classes can be administered on weekends for more than two students.

Note: We also offer two courses that focus on these topics separately; one on detailed drawing, and the other on advanced assembly. Both courses may be offered as week-long workshops. Call to inquire further.

Onsite Training: This and all Design-Engine courses are offered onsite at your facility as well. Call to speak to an account manager to arrange a class at 312.226.8339 today.

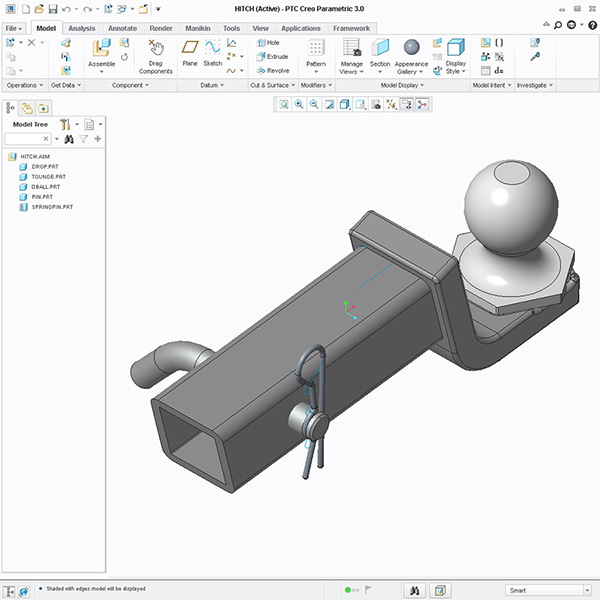

Projects: The instructor has a multitude of parts and drawings for class room participation.

Next Class: Learning Creo Surfacing WEEK long or Creo Top Down Design Training or Advanced Assembly week long intensive is recommended as a next class.

Prerequisite: learning Creo Training level 1 is recommended but not necessary.

Topics:

- Customize environment/map key development.

- Use cross sections in assembly drawings to aid in part design.

- Configuration and setup.

- Add and Manipulate GD&T.

- View Manipulation, Projections, Detail View, and Auxiliary View creations.

- Annotations, Dimensioning, Ordinate ASME standards.

- Parameters and how they work in a detail drawing.

- Manage drawings that contain family tables.

- Manage ASME standards in Creo drawing mode.

- Instead of hiding parts learn to use simplified reps.

- Manage exploded views in Creo drawing modes.

- Repeat Regions – automatically populate bill of material in assembly drawings.

- Learn to use drawings as a design tool for controlling snap fit and accuracy.

- Learn to manage inches and millimeters on detail drawings.

- Learn to use the draft entities tools inside drawing mode.

- Print, Import and Export PDF, IGES, STEP.

- Utilize advanced assembly functions such as skeleton parts & top down design.

- Learn to create title blocks and use parameters to automatically populate drawings.

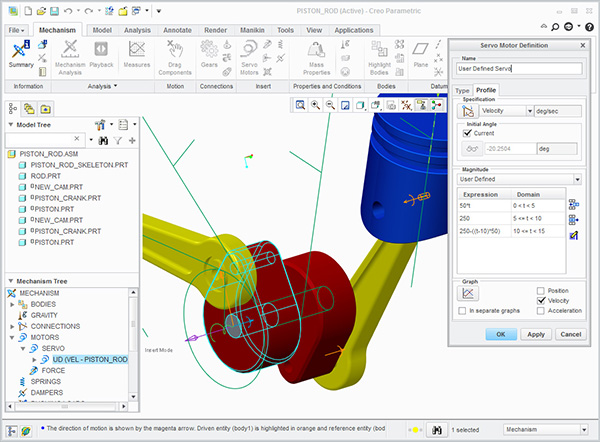

- Learn to use Mechanism in a serious introduction.

- Depending upon the instructor or class interests, we can administer a serious introduction to Creo Sheet metal.

Discussion:

- Discuss the use of geometric tolerance in Creo drawing mode.

- Discuss the use of parameters on detail drawings.

- Discuss cross sections and their many forms with respect to detailing.

- Discuss adding and modifying Creo detail notes and related workflow issues related to standard and custom notes on drawings.

- Projections, Detail View and Auxiliary View creations.

- Discuss standard drafting principals and relate those to Creo Drawing Mode.

- Discuss sheet metal drawings with examples on how to handle flat patterns in drawings.

- Discuss how administrators set up Creo drawing formats for the automatically populating data on company standard.

- Discuss output and strengths and weakness of exporting to PDF, DXF, or postscript for printing. Also discuss in detail printing to PDF with shaded view ports.

- Discuss symbols in Creo and their use with respect to workflow.

- Discuss Ordinate Dimensioning.

- Discuss setup files (.dtl files) with respect to workflow by switching between multiple .dtl files.

- Discuss the difference between fully dimensioned detail drawing from minimal control drawing with respect to six sigma.

- Discuss the new ASME adopted standard for 3D notes or annotations.

- Discuss managing drawing layers when parts contain curves and surfaces.

- Discuss managing exploded assemblies.

- Create various skeleton parts, publish geometry for various team members.

- Setting up constraints using Mechanism Design Extension and learn to export video.

- Learn to use servos within Mechanism.

- Utilize advanced assembly functions such as skeleton parts & top-down design.

- Learn to use Mechanism in a serious introduction.

- Top-Down Design in seven flavors.

- Create one-way associative models, which allows participants to inherit the changes from the parent model, and then make changes to the new model.

- Flexible Components ie. springs and cotter pins move as components exercise through their motion.

- Interchange Assemblies.

- Replace components in Creo Assemblies or Sub assemblies.

- Improve performance by simplifying large assemblies.

- Use a wide variety of top-down design tools to build the skeleton model.

- Use top down design to communicate among team members more effectively.

- Learn to auto generate Bill of Materials.

- Learn to pattern more effectuate with assemblies.

Brief:

This Creo course is a comprehensive detailing and managing engineering changes utilizing the latest release of Creo (was Pro/ENGINEER). This Creo course is developed for newer and seasoned users alike who want to become proficient at creating documenting and managing drawings and assemblies in just one-week. We help you learn Creo detailing and assemblies not by reading to participants from an exercise but by solving problems with this powerful tool set. We often depending upon participation cover 6-hours sheet metal or 6-hours mechanism within this class. In this course we help design engineers learn how to make changes quickly to set them up for becoming experts faster. As with all Design-Engine classes, participants keep the training material login and password for life.