About Design Engine

Work Smarter, Not Harder

Our Mission

Design Engine is a product development company.

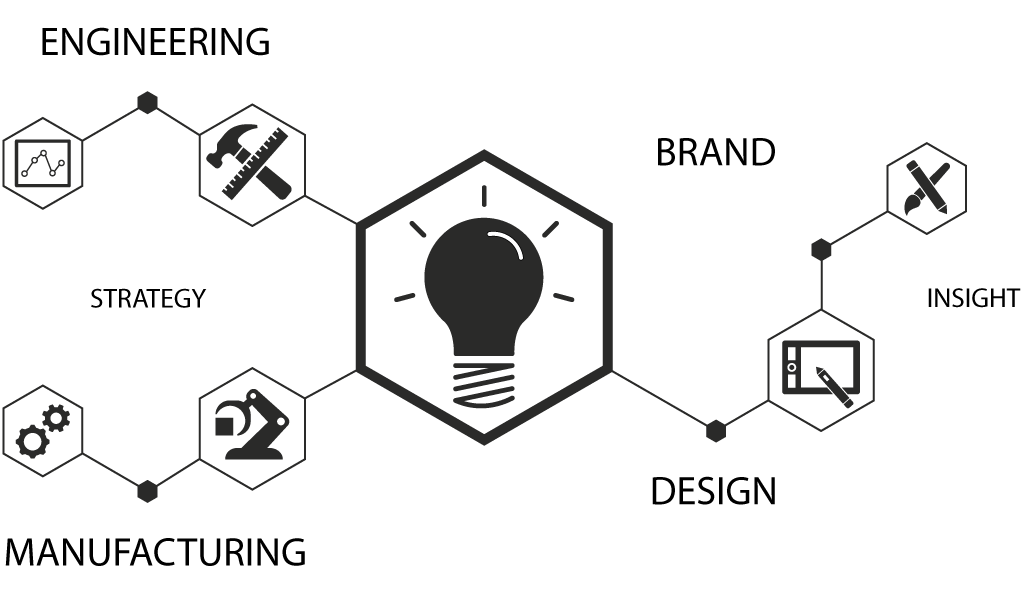

At Design Engine, we bring together a powerful team of industrial designers, mechanical engineers, & manufacturing specialists dedicated to helping product manufacturers bring bold ideas to life.

We don’t just design products, we help shape the future of how consumers interact with them. Our team is deeply invested in creating solutions that are not only functional and manufacturable but also emotionally resonant with the end user. From early concept development to production-ready engineering, we lead with insight, trend awareness, and hands-on expertise to help manufacturers deliver products that connect, inspire, and outperform.

When we hand over our deliverables, be it SolidWorks, Inventor, or PTC Creo, it’s extremely modifiable like you learn in our classes, leveraging parent child relationships like we do.

What we do

RESEARCH | IDEATION | PROTOTYPING | ENGINEERING | PRODUCTION | REVERSE ENGINEERING | TRAINING

Inquire for a capabilities overview today!

As researchers, industrial designers and mechanical engineers, we are also team builders. Whether we integrate into your team or do the lifting for you, we are well-equipped to take your product ideas from ideation to engineering, prototyping, production, and ultimately through to retail. Design engine maintains strong relationships with US and overseas manufacturers and US retail buyers. Like a smart puzzle Design engine is prepared to assist product organizations in one or all product development phases. It is often that our strength puzzles into your process neatly.

SPECIFICS: HOW WE MIGHT FIT IN

Research – Research means many different things depending on your problem and perspective. Understanding user needs, behaviors, and preferences to inform the design and development. A product that effectively meets those needs and provides a positive user experience can’t help but sell well.

Industrial Design – Ideation concept design that champions the research. Concept sketching, more carefully controlled concept sketches to color and material studies.

Product Engineering – Engineering is about understanding loads & performance, beyond preparing a product for production or focusing on DFM. Product design is the seamless integration of industrial design w/ manufacturing constraints to get products to market.

Electrical Engineering or Electronics – We don’t have electrical engineers on staff however we can partner with the right person or organization.

Prototyping – Prototyping means many different things depending upon your perspective or project. For some it’s simply 3d printing and cutting geometry on the mill to check fit. For others it’s having a specific ‘looks like production’ assembly of parts for a trade show. From Sheetmetal stands & tables, rifle forgings, cybernetic forms to machined surfaces we’ve done it.

Reverse Engineering – What reverse engineering means depends upon the nature and objectives. It could be you need our help to reverse engineer a motherboard or maybe it’s to reverse engineer a competitor product to learn about their specific patents to educate R&D and your legal department.

Manufacturing – Our CNC machines are not production ready either. Of course we don’t have manufacturing within our facility however we do know everyone. Of course we don’t have manufacturing within our facility however we do know everyone. Together we establish the criteria and we will find a manufacturing partner that will be a good fit for the project. From Die Casting, Plastic Parts, Co Injected soft touch TPE to forgings. We can make a good fit for your product or team.

Consulting & Contractors placement – We can offer you our team members who will fit nicely into your team for short or longer periods.

Delivery and Shipping – Prototypes get packed and shipped. The packaging can also look great, but it should protect as well. Sometimes we drive it to you with some assembly required.

Corporate Training – After the project we teach your team specifics about the model so taking over after we done has less anxiety. This course is often a week and offers customized specifics that your team will require to feel better about managing production or various engineering changes required for manufacturing.

"We detail out in an estimate precisely what we intend to do in each phase listing out assumptions and intended deliverables. ."

Bart Brejcha

What makes us special.

MANUFACTURING | DELIVERY & SHIPPING | TRAINING

When the project is designed and prototypes are available it might be time for changes or ready for manufacturing. In other instances your team facilitates the manufacturing. The tools we use inside the CAD can be intimidating especially with the use of Top-Down design or surfaced modeling. In those cases are offer training to the engineering team that will be managing changes ultimately managing manufacturing.