[dropcap]J[/dropcap]une 2015 Lego announces their intention to go 100 percent sustainable by 2030. A year later Lego is building their Sustainable Materials Center in Billun, Denmark, investing 125 million USD, and is in the process of hiring 100 experts to help them reach their goal. They have already started implementing some changes to Lego’s carbon footprint.

As Jørgen Vig Knudstorp, CEO and president of Lego Group points out in plastic news article, “There is no common definition of a sustainable material, several factors influence the environmental sustainability of a material — the composition of the material, how it is sourced and what happens when the product reaches the end of its life. When we search for new materials all of these factors must be considered.”

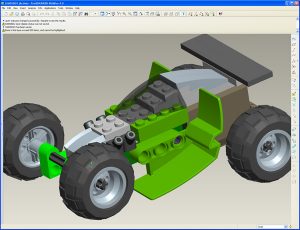

The vast majority of Lego’s environmental footprint comes from the creation of the raw materials used to make their bricks. (60 billion Lego bricks were produced in 2014). Finding materials that meet all the guidelines to create a sustainable brick is not an easy task. For instance bioplastics are made from a sustainable source, yet are seen by critics as not sustainable. Critics site that the amount of greenhouse gasses released when they decompose makes the material not recyclable. Lego is exploring recycled plastics along with many different alternative materials, and if they are successful finding an alternate for the ABS material, it will help dramatically reduce it’s environmental impact. This material may be something that is just now being created, and is not available yet.

With such a complex R&D process to alter; where are they starting? Packaging is one of the first alterations they have implemented. By altering the packaging Lego has saved 7,000 metric tones of cardboard in 2015. Energy is another. Kirkbi, majority owner of Lego’s, has invested in wind farms. Winter 2015, Lego began operations of their first wind turbines, a farm of 78 off the coast of Germany. Lego hopes to be running on 100 percent renewable energy by 2020.

Lego is leading the pack for sustainable design and products. As they continue to learn more and implement changes in their R&D process each step of the way, we hope that other companies will take note and tweak and adjust their carbon footprint.

Article written by Rebecca McQuillen for Design-Engine 13 Oct 2016