Design-Engine invites you and your team to network and learn at its monthly Chicago Pro/Engineer User Afterburn

What

Design-Engine hosted another monthly Chicago Pro/Engineer User Afterburn this past Tuesday. This Pro/E Creo user group symposium had two slated presentations. These Tuesday after work presentations at Design-Engine’s West Loop Studio (afterwork = afterburn) are from 6:00 to 9:00 PM (Tuesday, July 24th), and hope to offer shared resources, conversations, networking and maybe a resume or two.

Two presentations slated: one showed many new functions in Creo 2.0 (similar but not the same as last month) and the other presentation showed what it should take to be an expert at Plastic Part Design using Pro/E. Afterwards we had a conversation fueled by enthusiasm and a few beers. Since the presentation was focused on sharing plastic part design tips and tricks, SolidWorks, UG, and CATIA folks were and are always welcome.

Why

We are bringing back the former status of the Illinois PTC/User group – the largest PTC/User group in the world!

These informal after work user meetings will help us determine what is really wanted from you, the users, and how we can address your needs with future events. The main goal of these initial talks and presentations is to keep a momentum of visitors and to allow an inexpensive venue for Chicago area designers and engineers to share knowledge, learn, network, and grow.

Come early or late. Most importantly just come!

Theme

Bart Brejcha (a Design-Engine instructor) presented again what he thinks is cool in Creo 2.0 (others are encouraged to step up and share a few things or two).

Secondly Bart presented a talk on Plastic Part Design using Pro/E: What you should Know to be a Plastic Part Design Expert.

Here is a More Specific Look at What was Covered:

- Using top down design to delineate between parts

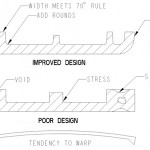

- Ribs go on with ease (demonstration). Discuss draft on ribs.

- Using parameters to control shell thickness and rib thickness so when the 20 changes trickle down from marketing you can handle the changes w/out having to pay so much attention to detail and make every change yourself. With parameters and relations everything updates automatically.

- User top down design to delineate between co-injected rubber portions and harder plastic options

- Using surfacing VSS to create draft when the draft feature doesn’t work

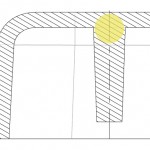

- Knowing the difference between core and cavity tools, that plastic shrinks, and that it can shrink around the core. This is why ejector pins are needed to push a product off the core. However, in some situations this can be avoided as plastic can shrink out of the cavity so you might get away with no draft

- Surfacing: Can you really be an expert at plastic part design w/o being a surfacing user?

- Shelling anything as one might opt to offset surfaces as opposed to shelling the geometry. The problem geometry might not be included in the surface offset thus creating a boundary blend

- Scraping off small shards of plastic into a small pile and burning them to determine the exact material make-up

- An even higher level of expertise would involve a group of parts that have to fit and work together… there is the potential of parts tolerances binding as in a switch that has to work in extreme temperatures. ANSYS can be used to determine fit problems.

Design-Engine also supplied pizza and refreshments.

Where

Design-Engine Studio 120 N Green St. Suite 605 dial #000 to get buzzed in. Come to the sixth floor and network with us.

When

July 24th 2012 – Expert Plastic Part Design: What you should know to be an expert

Future:

- August 28th 2012 – Surfacing in Creo 2.0 vs Wildfire: Building robust models that can be modified.

- September 25th 2012 – Designing with Mechanisms – With or Without Skeletons? How does Caterpillar do it?

- October 30th 2012 – Modifiability between Creo 2.0 and SolidWorks 2012: How robust is your modeler?

Looking for Presenters

Come show off your Pro/Engineer skills. In future meetings we can have three or more presentations. Did you solve a project problem uniquely using Pro/Engineer or Creo? Did you figure something out using Pro/Engineer or Creo that you think might benefit the collective? If you want to present please submit an email to Mike A. at: mike@designengine.com.