In our last post about sustainability in design we talked about how to use tools already in your design toolbox (i.e. CAD software) to quantify the environmental and social impacts of your designs.

So now you have clear goals and metrics for success – what are the tools in your toolbox to achieve them?

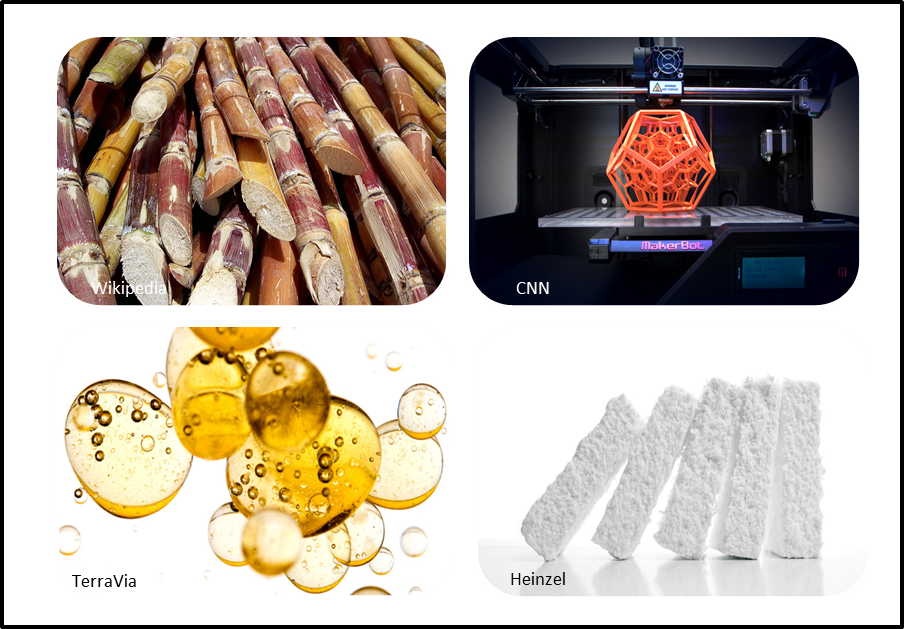

This edition talks about the future of more sustainable materials as one of those tools.

Materials made from plants (i.e., biobased materials)

When thinking about sustainable materials, most people think first of new material alternatives such as plant-based plastics or oils. There certainly is a lot going on in this space.

– The PET material used for Coca-Cola’s “Plant Bottle” is everything you know and love about PET, including its ease of recyclability; the difference is that it’s sourced from plants. Some breakthroughs are happening that would make it possible to reach 100% biobased sourcing for this PET.

– In general you see a lot of activity around sugarcane based plastics; Braskem, a major provider from Brazil, is supplying for a variety of packaging applications. Sugarcane often has a better environmental story than corn-based PLA, though the latter is still somewhat more widely known to engineers. Bonsucro and the Sustainable Sugarcane Initiative provide standards to monitor and measure this performance.

– TerraVia has made a name for itself supporting Unilever’s sustainability goals – they make a variety of materials made from algae. The primary application is as a food or cosmetic ingredient but keep an eye on this space for possible innovations in polymers, coatings, or other applications

There’s also a lot of talk, particularly in packaging, about the reminder that fiber can be managed as a renewable resource; it is after all the original ‘biobased’ material. As we learned in last week’s article, it’s important to evaluate the metrics on this first and validate that those metrics are the important ones for your stakeholders. In the packaging space it’s also important to note the distinction between biobased, meaning made from plants, and biodegradable, meaning that it can breakdown into smaller pieces in the environment (which is different still from compostable…)

No article about the future of design would be complete without a reference to 3D Printing. The business benefits of 3D printing are highly aligned with sustainability benefits – being able to create products or parts on demand, on location, means fewer resources tied up or wasted in lost inventory, no fuel or emissions associated with transport, and no waste in the manufacturing process. That said, 3D Printing is not a silver bullet for sustainability. Some issues exist related to the impact of the material used for the 3D printing including emissions from the printing process, toxicity of the materials, and of course, concern that the material itself is usually non-renewable petroleum polymer. As always, metrics and objectives matter.

While less immediately relevant to industrial design, a very notable development in the future of materials is the fact that many major specialty chemical firms like BASF and DuPont focusing on developing materials that contribute positive impact in terms of the sustainability metrics we’ve been discussing, while also themselves having a lower environmental footprint. A great example are materials that enable reduced water in a manufacturing process or that catalyze a reaction that otherwise required a lot of energy.

So what is the silver bullet? It would be great if an innovative new material appeared for immediate use that met all the cost, performance, and aesthetic requirements while having an improved environmental profile, but the reality is that the most innovative things you can do with design and materials is to spend more time thinking about the holistic design and the larger life cycle of the product system (including its supply chain). A product made with a less impacting material that still ends up in a landfill is likely not ‘sustainable’.

In other words, sometimes the most sustainable materials are the ones best designed for their application, even if they’re a material as old as manufacturing itself. Or, a more sustainable material in the future will be one that is produced with a more sustainable supply chain, regardless of the features of the material itself. Meaning, it’s made with fewer resources like energy or water, or with mores responsible labor practices, or with less waste and pollution. Chain of custody is one strategy to address this, and is common in particular for forest products like wood but including materials like sugarcane.

Whatever materials you are designing with, consider the source of those materials and end of life of the product itself. Could you add a few features to make it easier to disassemble the product for servicing or separation for recycling? Could you use materials that do have better recyclability rates for design projects where end of life is a priority? Learn more about designing for cradle to cradle and circular economy.

Sound like a lot to keep track of? Just be prepared to learn for the future – it won’t be perfect the first time, but as with all good design, fail fast, learn, and iterate for next time.

Article written by Laura Flanigan for Design Engine, October 28, 2016