SolidWorks: Advanced Modeling

Description

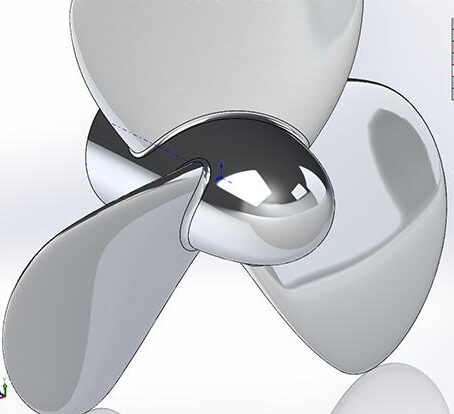

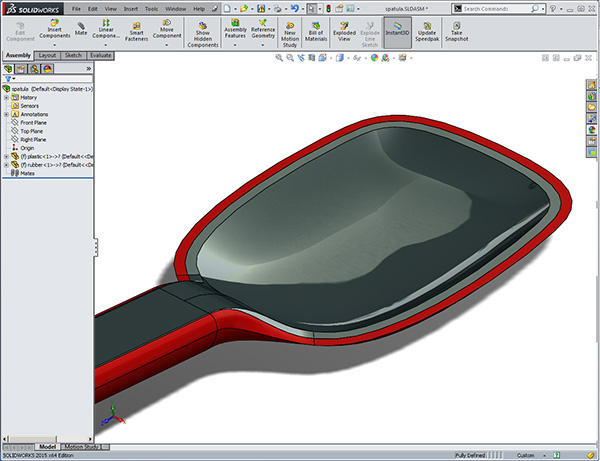

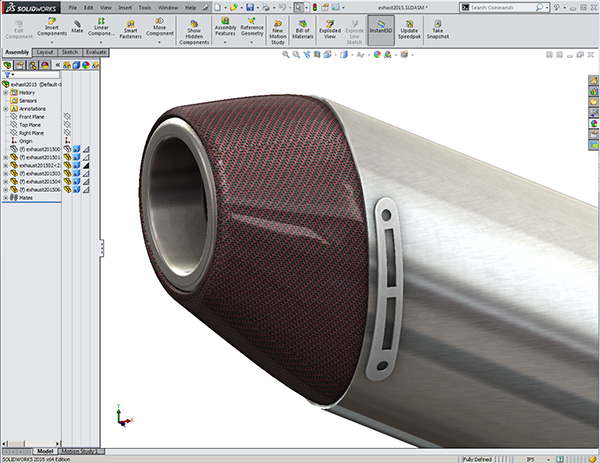

A great deal has changed with Solidworks over the recent years and chances are you are not leveraging the full potential. This course will highlight Advanced Part Modeling, Advanced Assembly, and making changes within the latest release of SOLIDWORKS. This training will help participants utilize advanced parts, sketching, and modeling techniques along with feature creation tools to improve product designs by making smart changes faster. Participants will also learn how to reuse existing design geometry when creating new robust design models. Topics can be customized for this class based on participants’ needs. This Advanced SOLIDWORKS intensive is developed for designers and engineers that want to become more seasoned users. This course is a must for the power users of any major manufacturer who are looking for a competitive advantage.

Topics

- Learn advanced selection techniques

- Create advanced datum features and utilize them in unique ways

- Use advanced sketching techniques

- Create drafts with complex parting lines

- Learn to use basic surfaces as design tools

- Explore surfaces with respect to top-down design/master moldeling

- Learn to manage and manipulate import geometry

- Create advanced offsets for shelling trouble geometry

- Learn to use top-down design for obtaining the soft touch delineation of a 3D model for manufacturing

- Learn how to use different advanced reference management techniques

- Learn to manage failed features more effectively

- Using curves to drive mechanisms

- Learn animation and motion analysis

- Learn to use Rendering more effectively

- Learn to use Equations effectively to create more robust models and create a non-proportional scale

Duration & Cost

40 hours = $2700 per student

For corporate rates, please call (312)226-8339

Prerequisites

Projects

- Prepare a motorcycle connecting rod model for FEA so that an iterative process for modifications is better utilized, i.e. make a change before each FEA is performed

- Prepare a prototyped part for Die Casting manufacturing by organizing parts that drive other parts based on specific machining operations

- This course is and will be customizable related to client/company projects

Discussion

- Discuss ‘piece-part modeling’ as opposed to the top-down approach

- Configurations with examples

- Multibody Geometry

- Excel Imports

- Discuss robust modeling techniques

- Discuss underlying curve geometry for making more robust models

- Taking products through to production. Ie. draft, compound parting lines, avoid sink or voids, using special tools to mitigate interference or clearance issues.

- Leverage and practice the new additions to Solidworks added in recent years.

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.