SOLIDWORKS: Sheet Metal Course

Solidworks Sheet metal training Description

Master the fundamentals of the sheet metal process in this comprehensive course. Participants will delve into sheet metal production, prototyping, and modeling, focusing on creating parts in SOLIDWORKS for manufacturing purposes. With over 50 customizable class models, the course caters to diverse needs.

Designed for both new and experienced users, this intensive two-day SolidWorks Sheet metal training course emphasizes practical skills over theoretical learning. Graduates retain lifetime access to training materials, ensuring continued growth and proficiency in SOLIDWORKS sheet metal design.

As with all Design-Engine classes, participants keep the training material login and password for life.

Solidoworks sheet metal training Topics

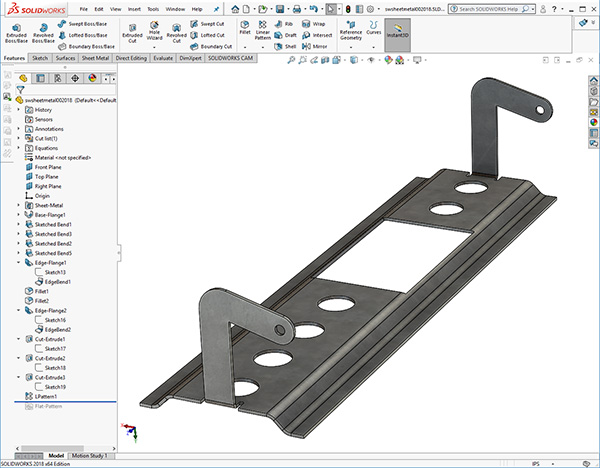

- Principles of Sheet Metal modeling

- Base Flange and Edge Flange

- Bends Folds and Reliefs

- Flat patterns

- Jog

- Lofted-Bends

- Miter Flange

- Joggle Geometry

- Rips

- Folds & Unfolds

- Corner treatments

- Forming Tool

- Offsets

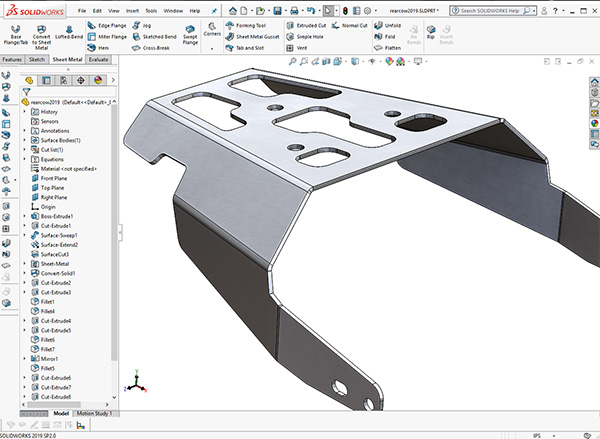

- Convert to Sheet Metal

- Patterns & Vents

- Louver & Dimple forming tools plus Custom forms

- Swept Flange

- Discuss pattern features and how to utilize them for sheet metal parts

- Discuss form tools and how to manage them on parts

- Learn to create and manage custom forming tools

- Discuss the difference between Normal Extruded Cuts vs regular Extruded Cuts

Duration & Cost

16 hours = $1650 per student

For corporate rates, please call (312)226-8339

Prerequisites

Solidworks Learn to Design or experience with SOLIDWORKS is recommended

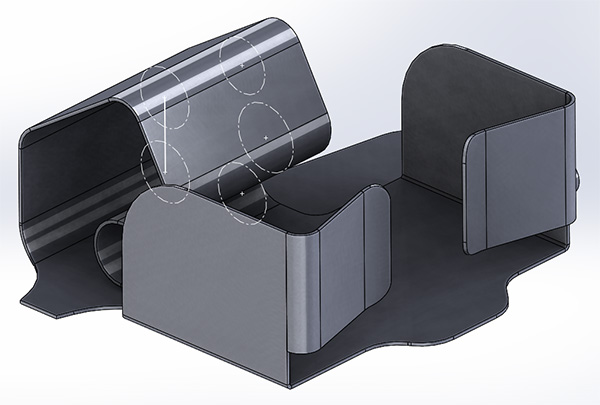

Solidworks sheet metal training Projects

- Layout and develop pivot .042″ Aluminum bracket then add a Flat State instance

- Build brackets with bends and extruded walls with a variety of challenges

- Model dust cover for back of computer using stamp form tools

- Create multiple parts that lock together i.e. sheet metal computer power supply

- Several Brackets, using Hem Bends, Deep Drawn Form, and combinations

- Explore various workflows for developing sheet metal components using ‘Convert to Sheet Metal’ techniques

- Create custom forms ranging from lances, louvers & dimples

- Develop a deep draw sink basin managed with a custom form tool

- Utilize Top-Down design in various forms to ensure proper fit and alignment

- 50+ Solidworks sheet metal models to choose as all of our courses are easily customized

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.