Manufacturing Week Long Comprehensive Workshop

Manufacturing Training Description

The course combines Design Engine’s Die Cast Part Design, Plastics Part Design, and Forging Part Design. We can also add Sheet metal to the Course couriculum. This course does not cover the actual writing of CNC code for numeric controls but could. Often the course can include sheet metal. Unless requested as those topics are covered in separate courses.

The Design Engine manufacturing courses are not for engineers new to using Creo or SolidWorks… unless the course is closed to your organization. This training is designed for both younger and experienced engineers who want to become more proficient in manufacturing products in just one week. We also help design engineers learn to make quick adjustments, accelerating their path to expertise.

Duration & Cost

40 hours = $2850 per student

For corporate rates, please call (312)226-8339

Prerequisites

Significant knowledge of Creo, SolidWorks or another parametric 3D CAD modeler is essential.

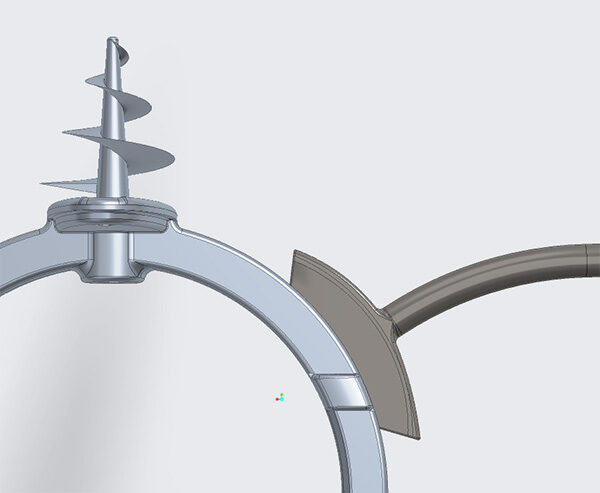

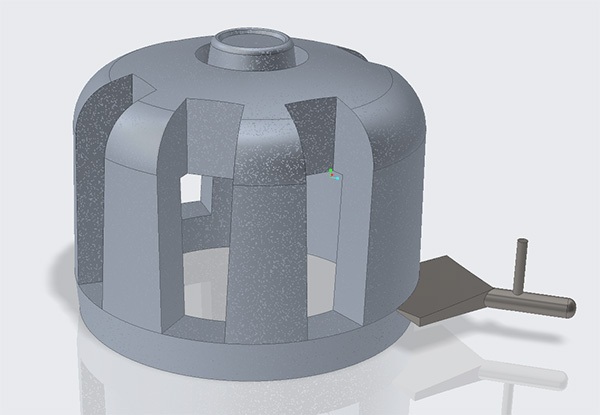

DIE CAST TOPICS & DISCUSSIONS

- History and Overview of the Die Cast process complete with tooling and outside machining operations

- Die cast molds, tooling, processing factors, nominal walls, radii & draft angles, ribs, weldlines, stress, cooling metals, bosses, and undercuts

- Snap fit, FEA, design recommendations, and overview of flow material using mold analysis software

- Discuss cooling time as related to thick sections of aluminum

- Discuss internal voids and fundamentals of other problems that occur from improper piece part design

- Discuss using parametric modelers and discuss examples where using variables with a parametric modeler to ensure your success

- Deep dive into using Draft and adding them to STEP files

- Learn to use surfacing and discuss its usefulness with die cast part design

*See the Design Engine Die Cast Part Design page for a complete list of course material.

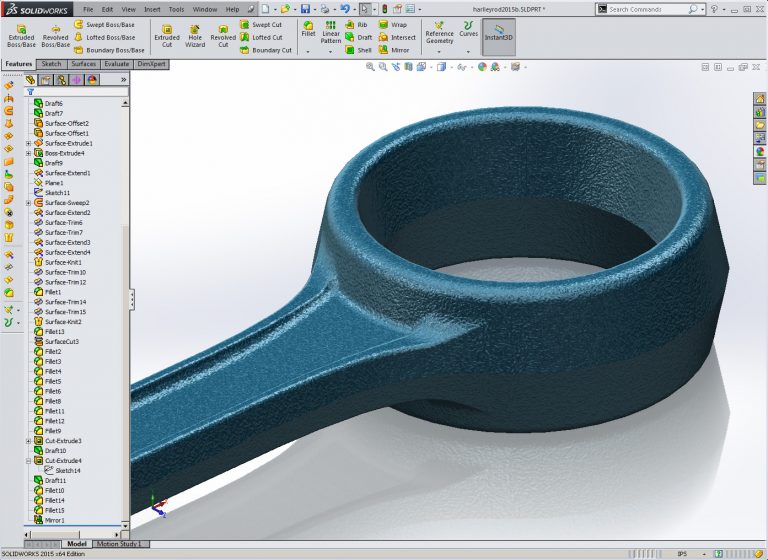

FORGING PART DESIGN TOPICS & DISCUSSIONS

- History and Overview of the forging process complete with tooling and outside machining operations

- Forging process by which metal is heated and shaped

- Discuss the progression of strikes

- Open Die Drop hammer forging and other examples

- Discuss alloys with respect to forging

- Compare cold and hot forging

- Discuss strengths and weaknesses of outsourcing

*See the Design Engine Forging Part Design page for complete list of course material.

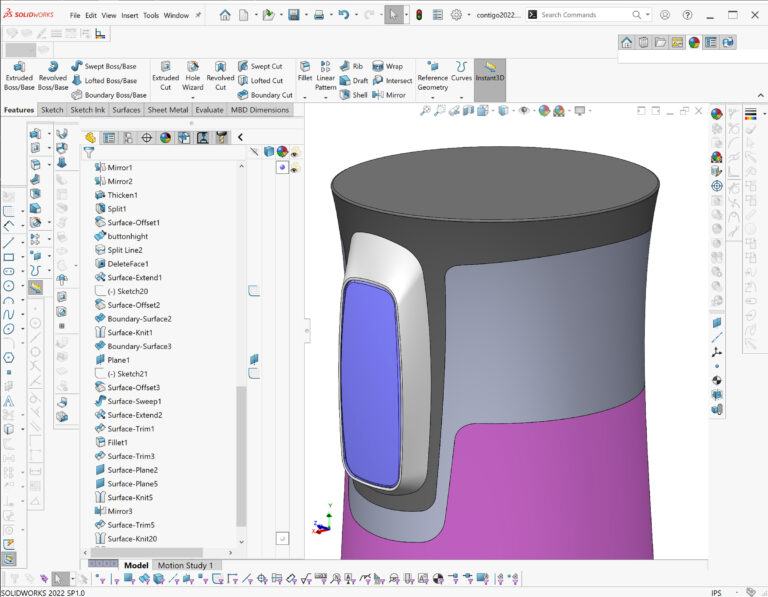

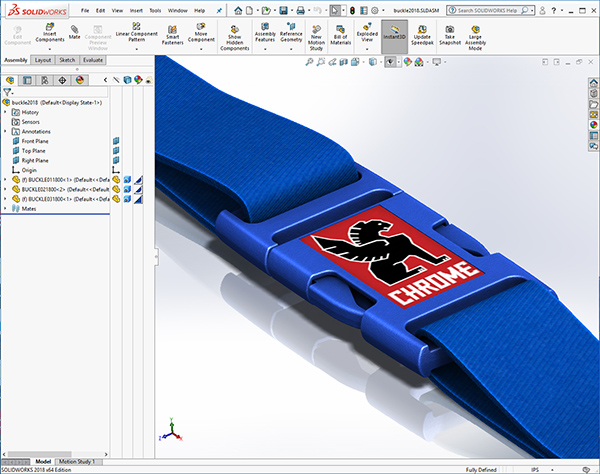

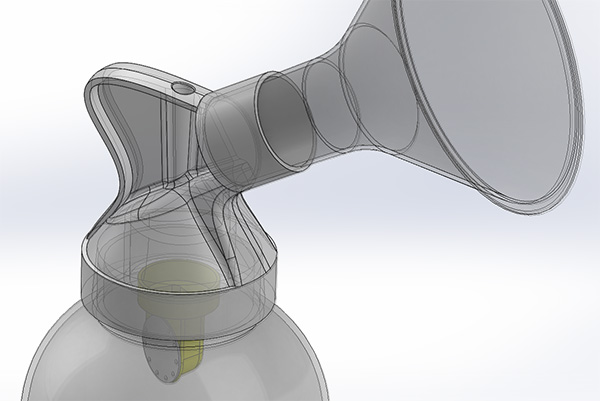

PLASTIC PART DESIGN TOPICS & DISCUSSIONS

- History and Overview of Plastic Part Design

- Discuss wide variety of rapid prototyping, processes & materials for Product Development

- Mechanical behavior of polymers for proper material selection

- Shrinkage, warpage and part ejection

- Discuss basic design elements in plastic part design: holes, ribs, thin wall features, bosses, nominal walls, and fill

- Discuss general rules for hollow boss design and discuss best practices.

- Learn about and how to avoid thin steel or thin blade areas

- Discuss designing undercuts with respect to Slides

- Discuss the interaction of Mold Filling, gating and weld lines

- General disclaimers on drawings

*See the Design Engine Plastic Parts page for a complete list of the course material.

PROJECTS

- Model parts with Top-Down Design

- Motorcycle brake Lever

- Pivot bracket

- Harley rod

- Motorcycle kickstand

- Participants will add Draft and prepare any number of parts for the plastic injection molding process

- Learn a light use of Surfacing

- Model parts with Top-Down Design

- Adding Draft to parts that currently have no Draft.

- Making parts moldable that others created

- Tips, tricks, and techniques for starting and completing plastic parts

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.

is it better to take the full week of plastics or the full week of manufacturing design?