Relativity Space is a start up that was founded in 2015 and is located in Inglewood, CA. CEO and co-founder and former blue origin employee, Tim Ellis, has created a company only 2 years ago. His co-founding partner, Jordan Noone, is a former Space X employee. The founders met one another in 2010 through USC’s student organized rocketry club. At Blue Origin, Ellis was heavily involved in integrating 3D printing for the CE-4 engine. Noone went to Space X after graduation, where he was involved with the dragon spacecraft before joining Ellis at Blue origin.

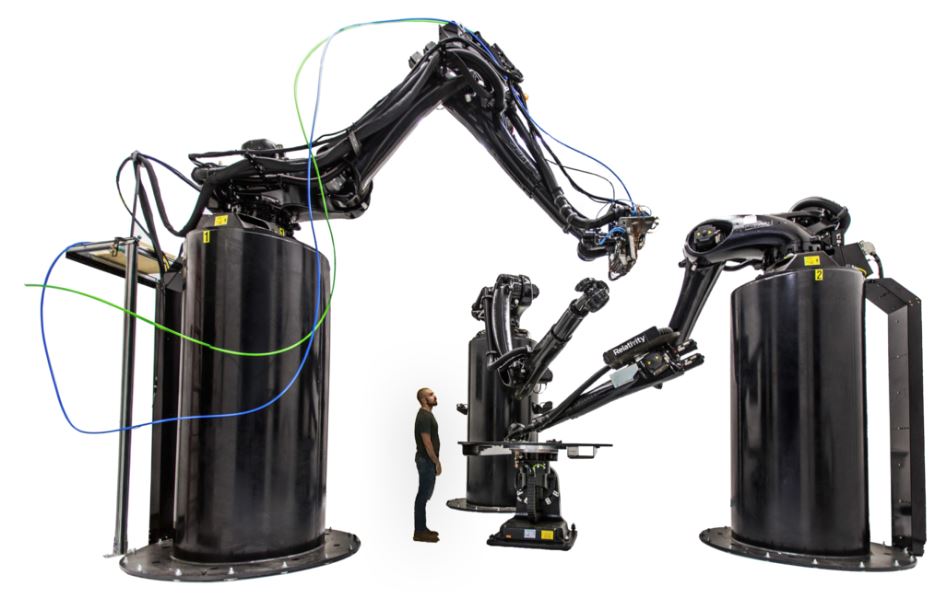

Rocket launches cost $100 million, but Relativity Space is on a mission to bring that cost down to $10 million a launch. They are completely changing the means of rocket construction. Relativity have a small staff of 17, and plan to be able to make rockets in only a few months using large 3D printers. In order to do this they were tasked with making their own 3D printers. These aren’t the printers kids are using at the local library, these are printing metal. The printers have large robotic arms that are approximately 20 feet tall and can deliver a fuel tank big enough for a rocket in just a couple days. They named their impressive 3D printer “Stargate”. Stargate is the world’s largest 3D printer. According to the company, Stargate is constantly getting smarter and faster by using sensors and reward function based learning. The team are creating an entirely new type of evolving production line. The team haven’t made an entire rocket yet but it has made a fuel tank and engine.

Photo courtesy of Relativity Space

Relativity have been able to secure $45 million funding. One of the investors is Mark Cuban. The team are claiming that they will be able to print 95% of the rockets. Components that won’t be able to be printed are items such as rubber seals and electronics. Most rockets are composed of about 100,000 pieces, this company is making a rocket with only 1000 parts.

Many times manufacturers use PTC Creo additive manufacturing design software to incorporate specific FEA tools into the design. In order to manage the frequency vibrations to withstand mach 5+ speeds all 3D missile heads are 3D printed for the past 15 years. PTC, the company that makes Creo 5.0, has an additive manufacturing module that when combined with vibration testing with Creo Simulate can organize a web like rib structure inside the titanium print for managing that specific frequency to avoid.

The new funding will enable the company to expedite its efforts to attain launch contracts. The company has been test firing with their Aeon 1 engine at their test site in Southern Mississippi. This test site acquired for 20 years through an agreement with NASA. Ellis states that a test flight is planned for 2020 and commercial launches are to begin in 2021.

Design Engine has new classes available for those interested in designing for 3D printing.