3D printing has certainly come a long way. However, one of the persistent issues remains to be the amount of waste 3D printing leaves behind. 3DomFuel, a maker of 3D printing filaments, has found a way to turn beer, coffee and hemp waste into usable 3D printing filaments.

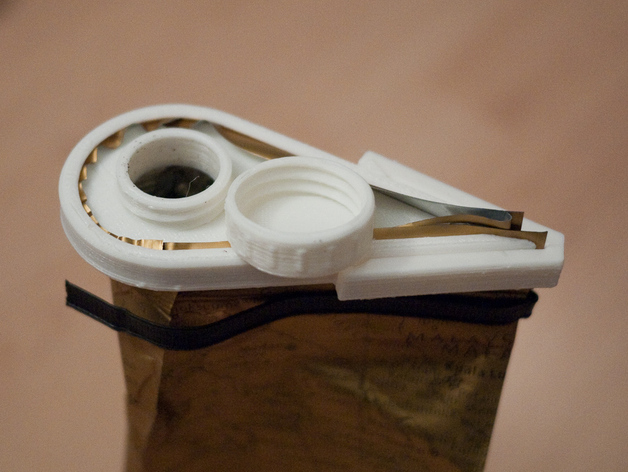

John Schneider, cofounder and chief marketing officer of 3DomFuel, realized early on that the 3D printing industry is already full of companies who supply traditional plastic filaments. He explained, “”We wanted to differentiate ourselves. We found a local company that specialized in mixing agricultural waste with plastics to create new materials. It was doing this with coffee waste from local roasters and we decided to try it.” They call this new plastic material 3D-Fuel. Specifically, the coffee filament is dubbed “Wound up,” and even smells good, “like a sweet latte,” Schneider explained. However, he was also quick to point out that the “Buzzed” beer filament does not smell like old beer. Once the 3D printing process using these filaments is completed, the smell completely evaporates. The “Buzzed” filament has been used to 3D print custom beer tap handles, coasters and even 6-pack holders. In addition to coffee, beer and hemp, 3DomFuel has been experimenting with other materials in an effort to supply the 3D printing industry with more recycled filaments. Schneider hopes that one day larger industries, such as medical and aerospace manufacturers, will adopt the use of recyclable materials and support a more sustainable manufacturing process.

For now these filaments cost about 60% to 80% more than standard plastic filaments but Schneider claims this hasn’t affected demand.

Interested in 3D printing? Check out our classes to get started.

[divider]

Article Written by Mila Medonaite for Design Engine, July 28, 2016