Solidworks Surfacing Training: WEEK ONE

Description

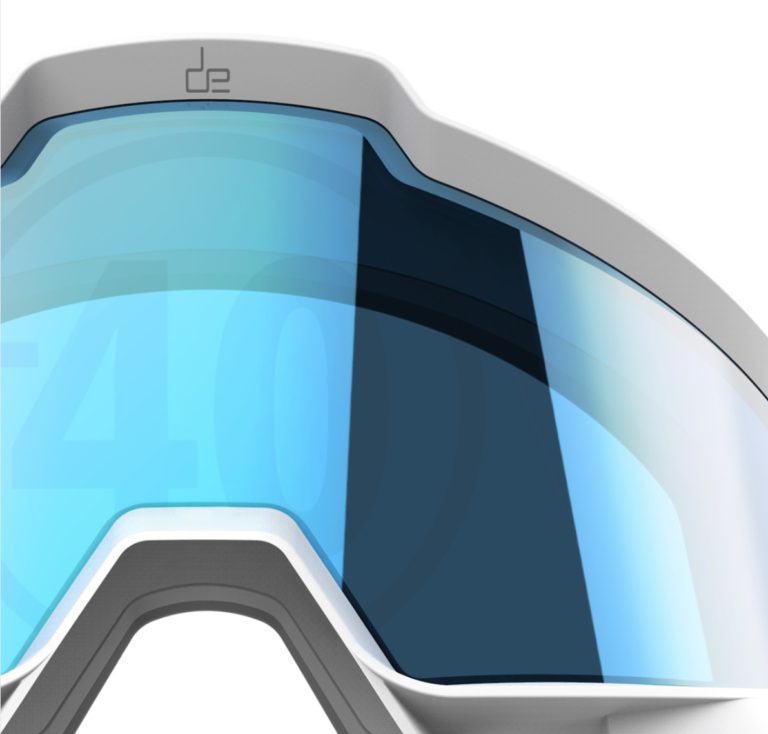

Learning Solidworks Surfacing is a must in this competitive work environment. Helping you become a surfacing expert is through the Solidworks surfacing intensive is our mission. This one-week intensive is a workshop that covers all the basics for advanced constraint based parametric Solidworks surface modeling. Learn surfacing with respect to ergonomics, plastics, stylized surfaces all with respect to how light reflects off of geometry. Engineers learn to work with industrial designers while industrial designers learn how to work engineers to understand form with respect to light reflections.

“𝗣𝗿𝗮𝗰𝘁𝗶𝗰𝗮𝗹 𝗮𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻: This Solidworks training course isn’t just theory. You’ll get hands-on with real-world examples, building your skills directly into practical projects.” Federico Fenoglio, ID Brompton Bicycles UK

Re-introduction to constraint based surfacing modeling using curves and surfaces & making changes utilizing the latest release of Solidworks. This Solidworks surfacing training course is developed for new and seasoned users who want to become proficient learning Solidworks surface modeling all in one week. We help you learn Solidworks, not read to you from a book. In this course we help design engineers learn how to make changes quickly to set them up for becoming expert faster. As with all Design-Engine classes, participants keep the training material login and password for life.

Topics

- 3D and 2D tangency curvature continuity then compare spline with style curves

- Split lines vs projection curves for building trims and other surface geometry

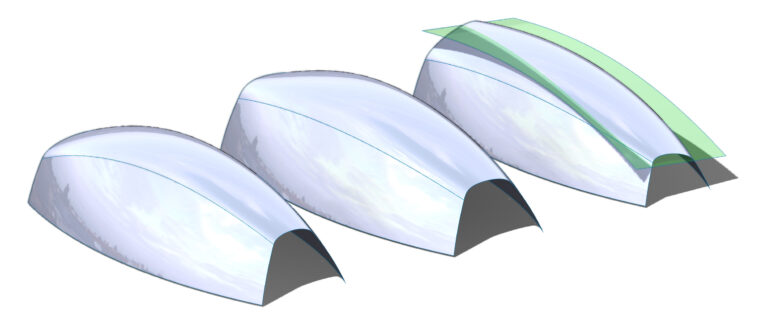

- Surface Loft, Boundary & Sweep functions

- Rhino or Alias Studio IGES and STEP import as SOLIDWORKS Import Diagnostics

- Surface Offsets with limitations

- Extend Surfaces, Surface Trims, and Knits

- Manage Draft using complex Sweeps

- Intersect, Projection, Composite, & Split-line curves

- Sketch spline curve on surface vs projection curve

- Use Equations to manage proportional updates

- G2 & G3 continuity and basics of Class A surfacing as precursor to Week 2

Duration & Cost

40 hours = $2850 per student

For corporate rates, please call (312)226-8339

Prerequisites

500 hours or Learn to Design with SOLIDWORKS is recommended

Discussion

- Alias/Rhino modeling technique comparisons with SOLIDWORKS for using a parent child constraint modeler

- Several Top-down design techniques including the use of Mid-Surfaces

- Using filled surfaces to resolve 3-part boundaries issues

- Learn to build resilient models and gain better light reflections

- Learn to create draft with parting surfaces

- Manage sweeps with respect to the pull direction in building plastic parts

- Techniques to better manage 2D and 3D IGES or STEP geometry with and without import Diagnostics

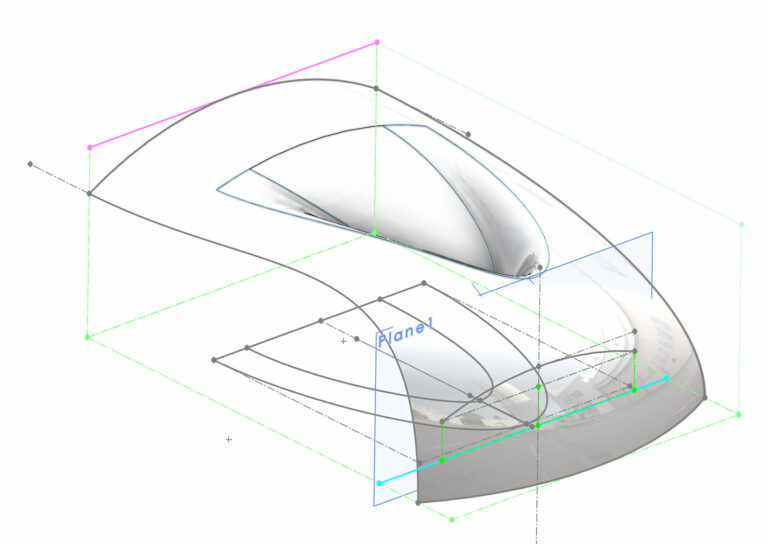

- Learn resilient modeling workflows utilizing bounding box geometry

- Discuss overbuilding with respect to tools and functions inside SOLIDWORKS

- Discuss a plan of attack; thinkmaps with modern day surfacing technique

- Manage over-molding or co-injection with tools learned in the class

- Utilize freeform to accomplish the same form without an internal curve structure

- Discuss using curve tools to manage light reflections

- Discuss G1/G2/G3 continuity; approaching G2 & G3, comb plots & light reflection in product design

- Discuss workflow by capturing form i.e building a surface model from a foam model

- Prove form by taking advantage of parent-child relationships and maximizing equations in sketches and features

Projects

- Most projects designed in class are customized to reflect the participants’ needs within a particular industry

- Examples of top-down design using SolidWorks and surfacing

- Spring steel skateboard truck

- FisherPrice children’s block toy

- Create special tool curves and surfaces that help manage surface geometry

- Plus several examples from the discussions and topics listed above

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.