Creo to SolidWorks or SolidWorks to Creo

Training Description

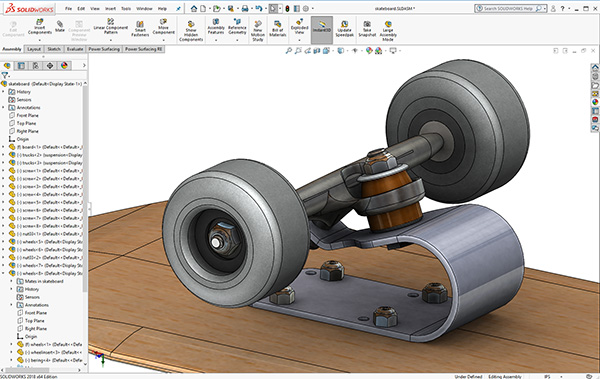

Focusing on constraint-based modeling, assembly, and detailing with the latest software release, this course is tailored for experienced users. You’ll learn efficient workflow techniques, going beyond basic demonstrations. We aim to empower design engineers to make swift, proficient changes, setting you on the path to expertise in just one week. This course is a must-have.

For teams still deciding on which CAD package to choose, we offer an unbiased, technical comparison. This 40-hour intensive course provides a comprehensive evaluation, enabling you to make an informed decision. In the Registration button below simply explain your situation and we will be happy to develop a custom course for your team.

Suggested training Topics

- These topics are suggestions, we can customize these courses if they are closed to your organzation

- SolidWorks or Creo sketch tools, including 3D curves

- Customize environment or map key development

- Learn proper part modeling workflow & technique, i.e. mirror pattern etc

- Get comfortable in failure mode

- Learn to use the user interface for speed and efficiency.

- Create features: Extrude, Ribs, Lofts, Patterns, Shell and Draft, Fillets using Equations to manipulate parts quickly

- Detail Cross sections, Parts, and Assemblies

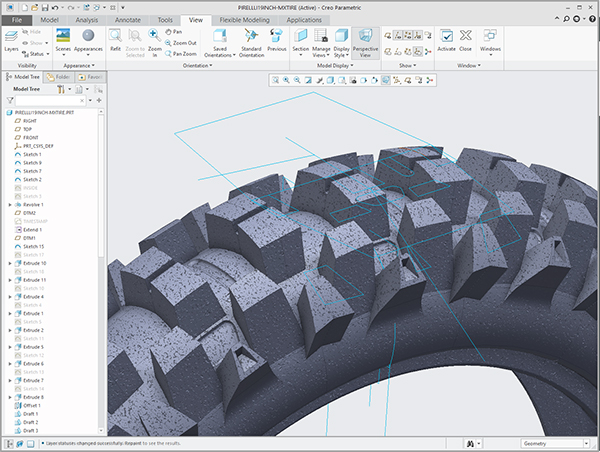

- Basic surfacing, complete with Sweeps and Lofts

- Utilize Edit Feature and Edit Sketch

- Learn to edit parts modeled by others, with certainty

- Learn to use drawings as design tools for controlling snap fit and accuracy

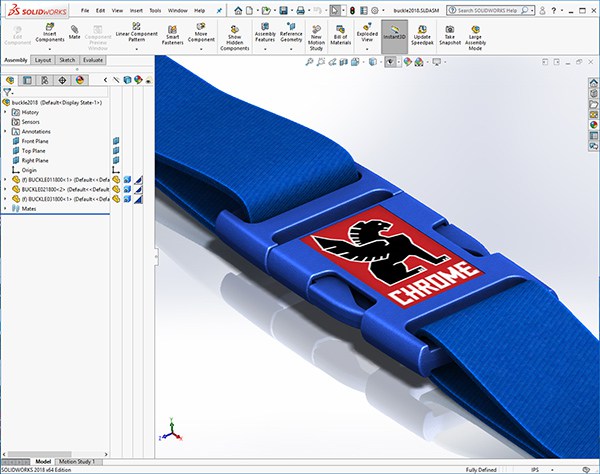

- Advanced Assembly function ie. mechanism, top down design, configurations etc

- Plastic part design & Sheet Metal basics, i.e. draft parting lines etc.

- Surfacing in both tools

- Basic assembly structures

- Using assembly drawings to understand then manipulate parts in context of assemblies

- Exploded Assemblies and automatic BOM

- Top-Down Design: master modeling, external copy, geometry, insert part

- Configurations vs Simplified Representations

- Creating mechanisms & smart assemblies

- Advanced Assembly functions

- Auxiliary views & cross sections

- Learn proper modeling techniques, to utilize drawings to aid in modeling, cross sections, exploded views, and the basics of surfacing

Duration & Cost

40 hours = $2850 per student

For corporate rates, please call (312)226-8339

Prerequisites

Participants should have a proficient working knowledge of either Creo or SOLIDWORKS.

training Projects

- Top-down modeling approaches for developing product

- Create detail drawings for documentation and assembly detail drawings complete with exploded views

- Build multiple bodies in Solidworks to using surface merges in Creo

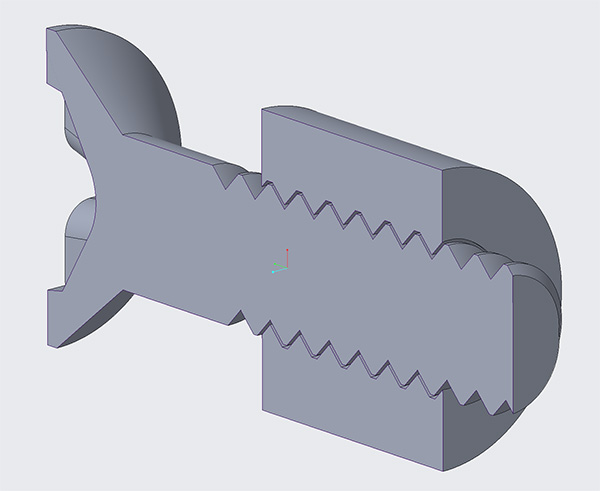

- Vice Example to learning to create assemblies with Creo or SolidWorks. Compare speed tools for both assembling a part to a pattern to copy and paste

- Compare cross sections in both tools and create a few cross sections in both parts & assemblies

- Several examples to compare SolidWorks sheet metal to Creo sheet metal with examples & exercises if applicable.

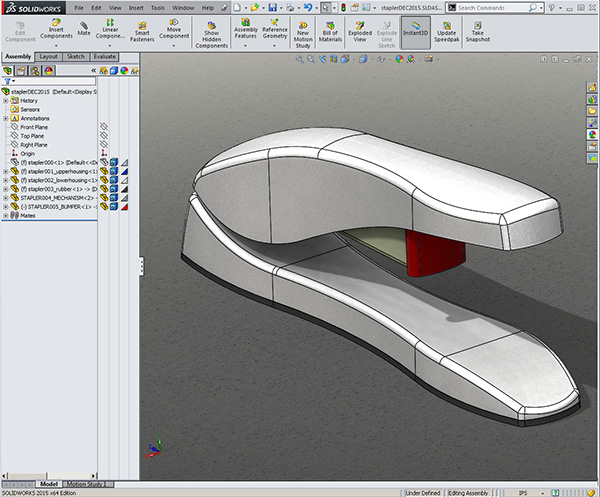

- The Stapler project helps participants compare with examples Solidworks surfacing compared to Creo Surfacing if applicable

training Discussions

- Discuss strengths and weaknesses of both packages

- Discuss basic workflow similarities and differences between Creo & SolidWorks

- Compare building reference planes with examples

- Making Changes & dealing with failures

- Discuss systems options in detail

- Examine editing parts others have modeled in both packages

- Compare using surfaces by themselves and within parts

- Group discussions designing mechanisms complete with surface detection.

- Compare Surfacing and Rendering tools

- Compare and contrast Sub’D or Sub Divisional tools. SolidWorks uses a Catia bridge for Catia Freeform

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.