Creo Advanced Heavy User Custom

Description

First developed as a training course custom-built for a corporate client, this Creo training course could cover a mixture of ANYTHING you may specifically require. Plastic part design, die casting, Pro/Program, Advanced Creo Surfacing, exporting to other CAD programs, etc. This class can come tailor-made for your team with projects, training materials, and videos specific to your team. Invite us for an online discussion today!

Suggeted Creo Training Topics

- Advanced Creo, Creo Surfacing, and Pro/Program

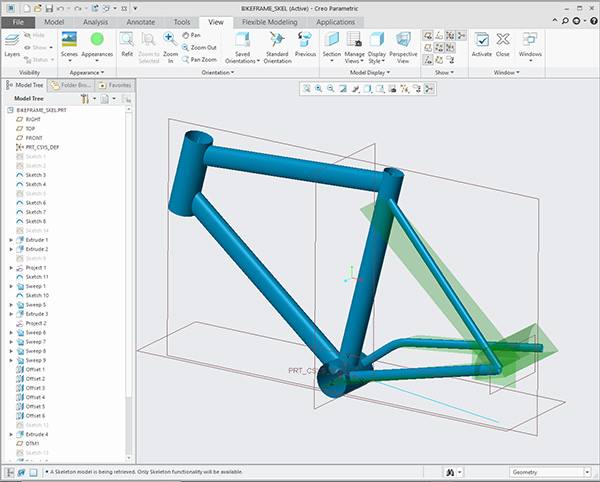

- Top-down modeling, master model, and skeleton techniques

- Alias/Rhino to Creo transfers ie. creating parametric data out of the import

- Comparing Solidworks to Creo specifics

- Edit definition or redefine functions

- Tips and techniques for growing into advanced users

- Discuss in great detail the Top-down Design approach

- Enhanced study of Sketcher

- Force assumptions, replace, and rotate in Sketcher

- Force patterns to follow complex curves

- Create advanced sweep

- Blend & Sweep features

- Bodies

- Creo Simulate

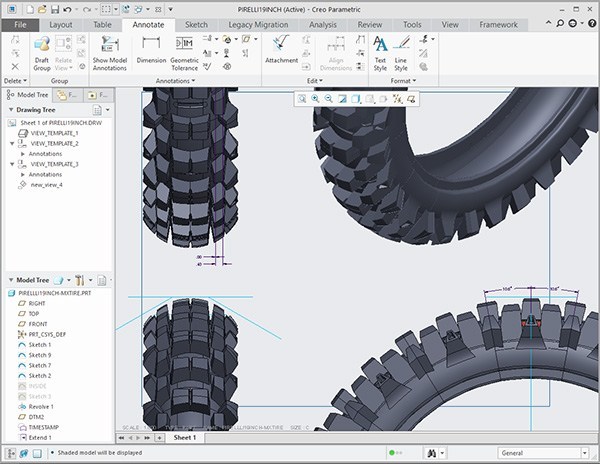

- GD&T

- Table, repeat regions for the automatic bill of material generation

- Build gears in a robust, fast, and uncomplicated way

- Gears: helical, spur, and pinion

- Learn to utilize driving actions ACME screw gears

- Create profile-producing equations

- Make gears using parameter tables and relations

- Convert Cartesian coordinates to Spherical Coordinates in sketcher to use later in equations

- Notes & Examples of Creo Update specifics

Duration & Cost

16 hours = $1650 per student, or 40 hours = $2850 per student

For corporate rates, please call (312)226-8339

Prerequisites

1,500 hours minimum experience with Creo

Projects

All the projects in this class are based upon student interests, job requirements, or company projects.

Discussions

- Discuss many forms of cross-sections

- Detailing and understanding interference inside an assembly

- Compare global interference checks

- Planning out Skeleton Models to manage your project

- Basics of surfacing to make robust changes that propagate the entire set of parts without failed features

- How Top-down design offers participants greater flexibility and control over the entire structure

- Discuss how teams can be more effective using published geometry

- Using copy surfaces effectively as ‘timestamps’ for managing what ultimately gets published

- Compare shrink wrap & other forms of external copied geometry for managing large assemblies

- Reference viewer for understanding skeleton parts

- Constraints with Mechanism

- Saving and retreating large assembly representations in order to save time

- Learn to use motion skeletons to manage mechanized assemblies

- Substitute simplified versions of assembly components without losing constraints

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.