Creo Mechanism Dynamics Intensive

Description

Introduction to high-end constraints utilizing Creo Mechanism in the latest release of Creo. This Creo training course was developed for new users looking to become proficient within two days. We help you learn Creo Mechanism through exercise, rather than a textbook-read approach in order to set participants up for becoming an expert faster. You will learn to use connections and drivers to build elegant assembly models using existing Creo parts. By providing a concurrent simulation of potential interference over a range of motion. This resolves failures before prototypes are created. The end result will be reduced design time and higher design confidence.

Topics

- Basics of high-end assembly constraints

- Mechanical degrees of freedom concepts and relations to an assembly

- Use Connections instead of Constraints

- Types of connections: Sliders, Pins, Gears, Slots, Cylinders, etc.

- Move your mechanism manually by “grabbing” it with your virtual hand

- Create motors or drivers to automatically move complicated assembly apparatus with equations and tables

- Utilize collision detection to manipulate assemblies

- Understand the types and effects of dynamic motion (position, velocity, and acceleration) when choosing the right driver equation or table

- Dynamic global interference checks

- The output of digital movies to link to Powerpoint for presentations

- Discuss the use of the Creo Mechanism powerful tool with other simulation and optimization tools, i.e. Mechanica

- Perform optimization studies and find motion envelope information

- Learn to perform dynamic global interference checks; utilize collision detection

- Create assembly demonstration presentations

- Convert an existing Creo assembly into a Mechanism assembly

Duration

16 hours = $1650 per student

For corporate rates, please call (312)226-8339

Prerequisites

Previous experience with Creo Assemblies

Projects

- Build a simple Four Bar Linkage; experiment with interaction of various-sized links

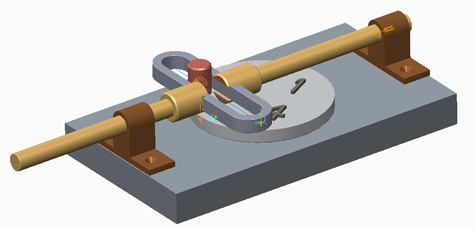

- Create a Slider-Grinder apparatus

- Create a Clamp Assembly; observing rotation, equilibrium point, clamp lock, etc.

- Assemble piston and crank parts; use servo motors to power the configuration

- Create a Backhoe Linkage using simple parts and constraints

- Create snapshots of mechanisms at initial and final positions

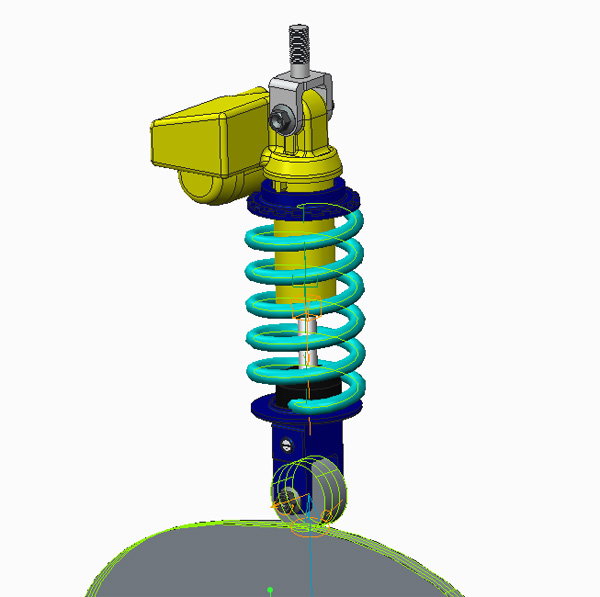

- Build a slider mechanism to convert rotational to linear actuation; run analysis between each new addition of springs and dampeners

- Explore Collision Detection tools with a GoPro camera housing and Latch Mechanism

- Piston & rod assembly: add a servo to spin up the assembly. Utilize position tables, Velocity and Acceleration equations to generate MOV files

- Convert an assembly of your choice into a Creo Mechanism Dynamics assembly and output the results in the form of a movie

- Utilize Theo Janson’s Kite walker supplied models and rebuild them as pin & cylinder constraints

Discussions

- Purpose and functionality of the buttons while in Mechanism mode

- Discuss the differences between using a Pro/Skeleton and a Pro/Mechanism to simulate motion and the effects of design changes with each method

- Pro Simulation measures and load graphs in the context of Mechanism

- Discuss connection order and component packaging loops for fully constrained assembly

- Difference between pin & cylinder constraints

- Discuss external references and assembly etiquette while creating mechanized drivers

- Pros and cons of each type of driver table, i.e. Position, Velocity, Acceleration, to simulate type motion

- Use Mechanism functions to limit the motion so as to simulate reality

- Learn to create Gear Constraints for Spur, Bevel, Worm, Rack & Pinion Gears

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.