Die Cast Part Design Intensive

die cast training Description

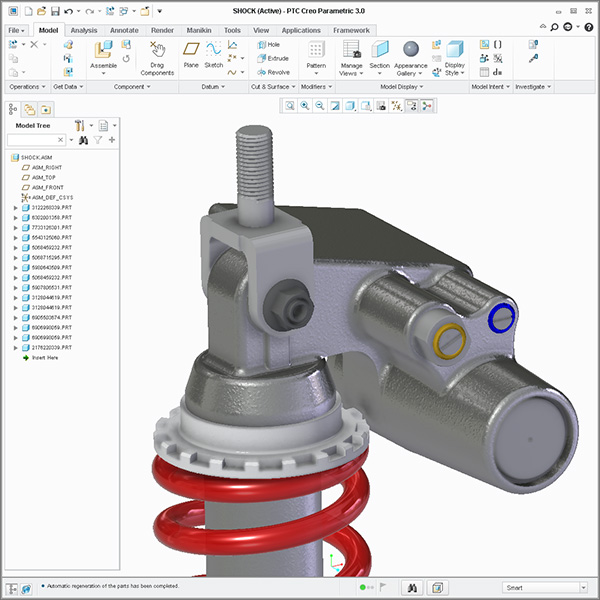

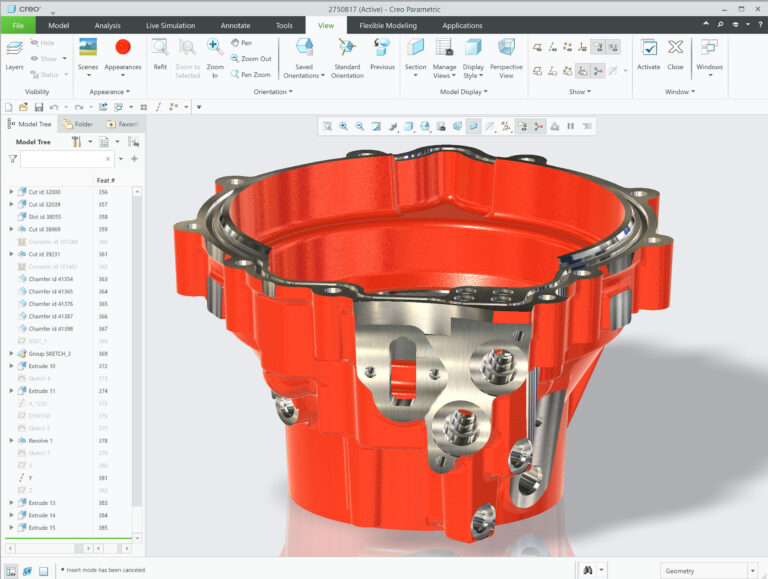

Introduction to Die Cast Part Design using a constraint-based modeling utility such as SOLIDWORKS or Creo. This product design training course along with the related material will bring confidence and a working understanding of the die-cast process to your team. The majority of time will be spent on processing lectures and the part design requirements imposed on the designer by the Die Casting process within your respective CAD design tool of choice.

- Compare metal injection molding, powder injection molding, and die-casting

- Conventional Die casting vs Gravity fed mold comparing prototype alloys

- Die casting vs forging process with respect to cost and quantity

This product designers training course is developed for new and seasoned engineers who are looking to become experts in Die Cast Part Design within a short amount of time. In this course, we help design engineers understand the power of die-casting, make better decisions for die-cast parts for production, learn how to create more complex geometry, make changes quickly & estimate projects.

Design Engine suggests that anyone on your team with less than 4 years of experience using SolidWorks Training or Creo Training should seriously consider taking these linked above Design Engine ‘Learn to Design’ courses first. This will free up more time for the advanced portion during the remaining 3 days of the die-casting course. The Learn to Design courses also uses various die-casting examples complete with machining operations on separate part numbers in the exercises.

die cast training Topics

- Die Casting Overview and in-depth discussion with respect to the various die casting processes.

- Overview of flow mold analysis software

- Steps for the die casting process

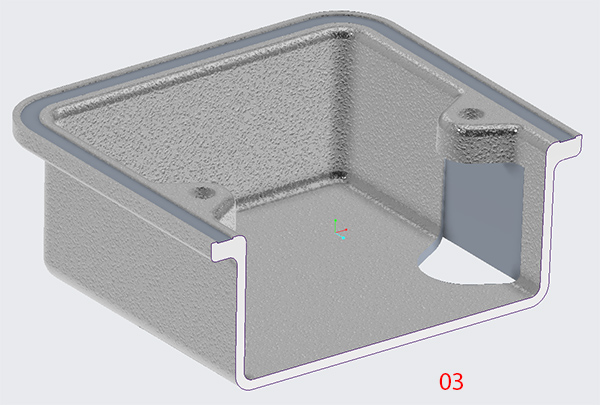

- The process, die cast molds, tooling, processing factors, nominal walls, radii & draft angles, ribs, weld lines, stress, cooling metals, bosses, undercuts, Snap Fit, FEA, design recommendations

- Learn to design molded undercuts and side pull options relative to cost

- Learn about factors in choosing the proper alloys with respect to die casting, i.e., zinc, aluminum, magnesium, copper, lead, and tin

- Discuss material properties, such as adding zinc and copper for more malleable alloys, i.e., faucets

- Learn about the metal mold itself and many of its intricacies, such as sleeve ejection, how it is cooled, sprue and runner, ejector bars, ejector plates, and ejector pins

- Finish machining and discuss die-cast specific alloys

- Compare Die Casting to Plastic Injection processing, one of many various discussions.

- Learn SolidWorks & Creo modeling techniques, minimizing gas porosity

- Learn about heat treatment, anodizing processes, and heated-manifold direct-injection die casting

- Fastening & Joining

- Bosses and ribs with respect to mold-ability, 70% rule, Solidworks equations or Creo relations & keeping the parts steel safe

- Discover and discuss various prototyping strategies

- There are several modeling challenges presented in either Creo or SolidWorks

- Learn about the benefits of joining the North American Die Casting Association

Duration & Cost

16 hours = $1650 or 40 hours = $2850 per student

For corporate onsite training classes & rates, please call (312)226-8339

Prerequisites

General knowledge of Creo or another parametric 3D CAD package is recommended

die cast training Projects

- Learn to use Top-down design with examples in either Creo or SolidWorks

- Draft as related to texture kits. Discuss how to call out textures in drawing programs with examples. Learn about the texture application process and why die cast parts often recess the texture

- Use surfacing and discuss its usefulness with die cast part design

- Examples using variables with a parametric modeler can save problems in the future complete with in class examples

- Use parameters to drive geometry relative to nominal wall thickness

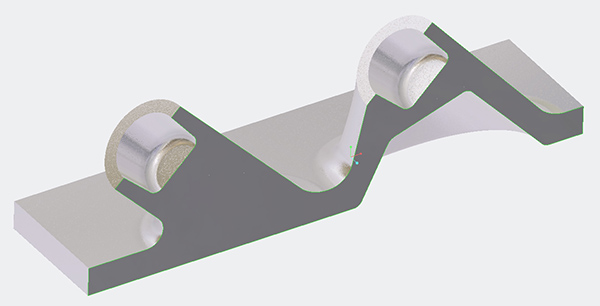

- B-Side geometry creation techniques including secondary operations

- Techniques for managing prototypes so that they can be tested as if those parts were production die cast parts

- Add Draft to parts that currently have no Draft and utilize Draft check correctly

DIE-CAST Discussions

- History of forming metals and die casting as a process

- Discuss how a die cast mold process works in hot chamber vs cold chamber in detail

- Discuss the strengths and weaknesses of outsourcing tooling and partnering with local die casters molders

- Discuss basic design elements, i.e. holes, ribs, thin wall features, bosses, nominal walls, and fill

- Discuss best practices and general rules for hollow boss design with ways to avoid thin blade situations

- Advantages and disadvantages of die casting vs plastic injection

- Discuss gating and problems such as fill vent and eject issues

- Various methods for cooling in general + specifics to cooling smaller core geometry

- Discuss how to design with solutions to potential cosmetic problems

- Cooling time as related to thick sections of aluminum

- Discuss internal voids and fundamentals of other problems that occur from improper piece part design + solving problems with high integrity die casting vs conventional die casting

- Discuss the die cast vendor role and how design engineers might better leverage their experience

- Learn about tooling and materials for die casting from a machining point of view; compare to cutting graphite for electrode burning of steel

- Discuss how to improve flow of the melt through the mold and learn about Flow Molding analysis software

- Learn to design and test die cast parts with specific elements to anticipate a certain amount of failure

- Discuss general disclaimers and other associated notes that engineers might find on detail drawings

- Discuss what challenges a mold designer faces when designing a mold with respect to cooling

- Discuss specific techniques for managing the Creo or SolidWorks machining features, with separate part numbers

- Discuss Draft in its many forms complete with examples of split Draft. Also to use surface modeling to effectively form required draft.

- Discuss component finishing applications plating, painting, or powder coating processes in detaild

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.