Creo Advanced Assembly Intensive

Creo Advanced Assembly training Description

Participants in this week-long Creo Advanced Assembly training intensive will learn to manage large assemblies with or without top-down design, utilizing various tools within the Creo Advanced Assembly Module. The course can focus on any combination of the following topics: large assembly management, Mechanism Design or MDO, welding, Top-Down Design, and managing co-injected handheld products.

This Creo Advanced Assembly Training course aims to teach participants how to effectively use the Creo Advanced Assembly Extension (AAX) and become experts within their organizations. By mastering the Advanced Assembly Module, participants will learn to manage large assemblies more efficiently, design mechanisms, lead teams with top-down design, and utilize flexible components, configuration rules management, assembly process planning, and hundreds of other tools. Expect increased design speed, reduced time for changes, and more robust models.

Creo Advanced Assembly or AAX streamlines the flow of information from design to manufacturing.

creo advanced assembly training Topics

- Quick overview of the latest released Creo

- Learn to create assembly references in one part to another part through an assembly where participants can break the references to the assembly or any of the parts.

- Learn to manage large and exploded assemblies to mitigate drawing regeneration time

- Customization beyond base install of Creo for Large Assembly management

- Instead of hiding parts to simplify your design, learn to use simplified reps in order to save and retrieve later

- Workflow with Large assembly management in mind. Manage 1700 to 17,000 parts effectively with various large assembly management tools that are not available in mid range modelers or the base package of Creo

- Utilize advanced assembly functions such as skeleton parts, top down design, envelopes and shrink wraps

- Serious introduction in using Mechanism and Import Data Doctor

- Top-Down Design in seven variations, including published geometry reasoning, set up and implementation to build skeleton models

- Learn to use motion skeletons for mechanized assemblies

- Flexible Components ie. springs, nylon straps and cotter pins move as components exercise through their motion.

- Interchange Assemblies

- Replace components in Creo Assemblies or Sub assemblies related to shrinkwrap parts in an effort to mitigate large assemblies

- Improve performance by simplifying large assemblies

- Use top down design to communicate among team members more effectively

- Learn to auto generate Bill of Materials with Repeat Region tables

- Learn to effectively import IGES or STEP data into Creo then utilize techniques for managing large import assemblies

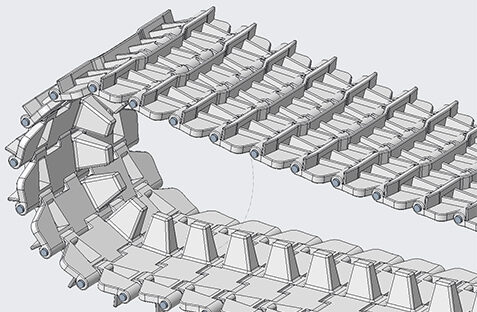

- Learn to pattern more effectively with assemblies

- Set up constraints using Mechanism Design Extension and learn to export video

Duration & Cost

40 hours = $2850 per student

For corporate rates, please call (312)226-8339

Prerequisites

Significant experience with Creo is recommended or the Creo training course Learn to Design.

creo advanced assembly training Projects

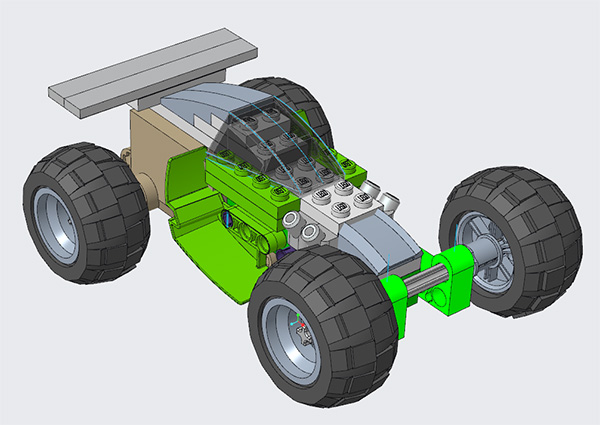

- Create and save off various simplified representations for a supplied Lego racer model then open the project by a simplified rep after saving

- Make changes to skeleton parts with confidence so modifications propagate to the various piece parts

- Remove and add a variable component back to an assembly for a BB gun mechanism or motorcycle front forks assembly

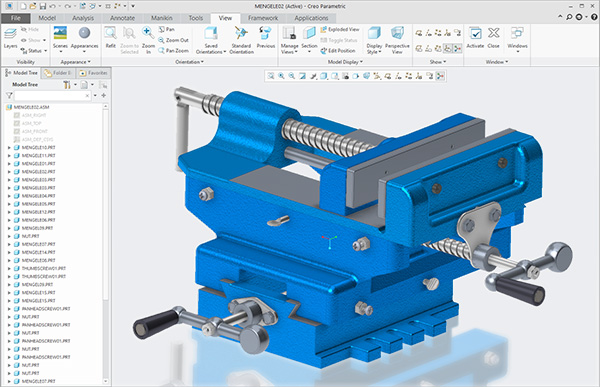

- Substitute large assemblies with Shrinkwrap geometry on drill press vise assembly

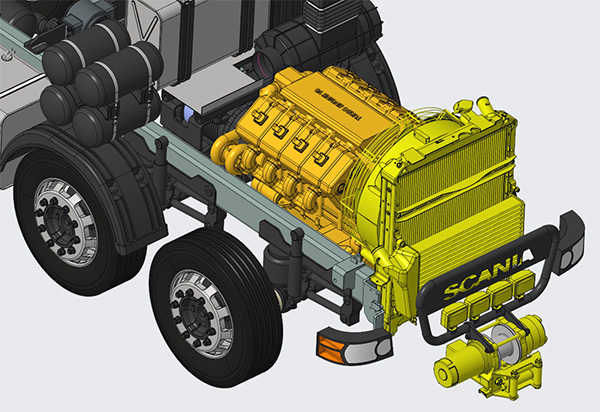

- Import large assembly STEP data; modify and change various import data on Diesel Engine

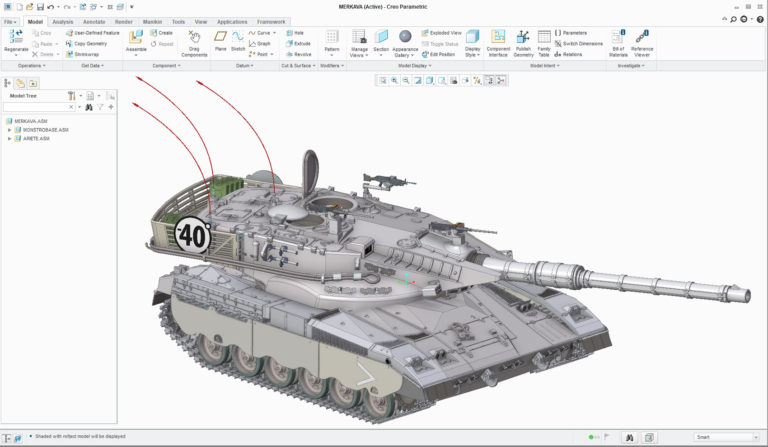

- Use Shrink & Envelopes to create mounting brackets for Merkava Tank

- Create one-way associative models, which allows participants to inherit the changes from the parent model and make changes to the new model

- Create various skeleton parts, publish geometry for various team members

- Use Lego piece parts to practice creating simplified representations

- Create piece parts from delineation geometries in surfaces

- Create shrink wrap model for others to utilize while exploring the strengths and weaknesses of this workflow

- Create a Piston & Rod assembly with curves while controlling the path of rotation and allowing parts to exist off the shelf before we mechanize it

- Four-bar mechanized assembly

- Pepper grinder

- Belts & pulley mechanism

Discussions

- Discuss cross sections and their many forms with respect to detailing and understanding interference inside an assembly as compared to global interference checks

- Compare Creo tools to other mid-range engineering tools, such as Solidworks & Inventor that don’t have the option for a module for advanced assemblies like AAX

- Planning out Skeleton Models to manage your project

- Basics of surfacing to can make robust changes that propagate the entire set of parts without failed features

- How top-down design offers participants greater flexibility and control over the entire structure.

- Discuss how teams can be more effective using published geometry

- Discuss using copy surfaces effectively as ‘timestamps’ for managing what ultimately gets published

- Compare shrink wrap & other forms of external copied geometry for managing large assemblies

- Reference viewer for understanding references across skeleton & reference parts

- Constraints with Mechanism

- Discuss Simplified representations in all forms. Also saving and retreating large assembly representations in order to save time

- Learn to use motion skeletons to manage mechanized assemblies

- Substitute assembly components with simplified versions without losing constraints

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.