Creo Mold Design

Description

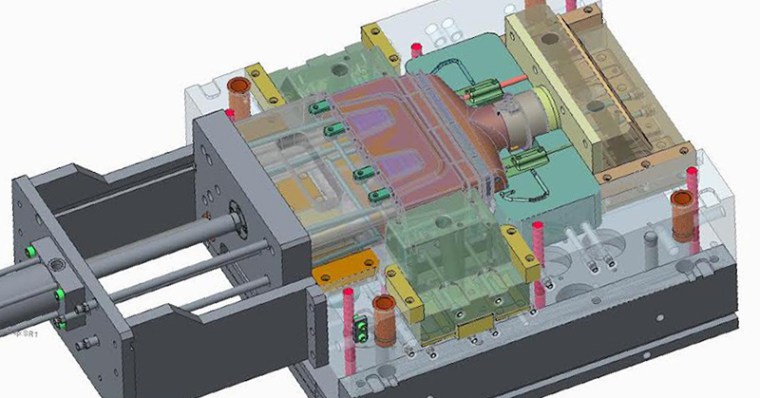

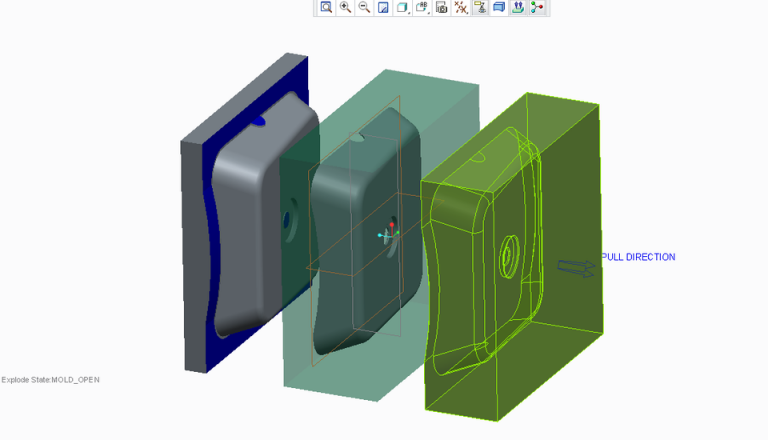

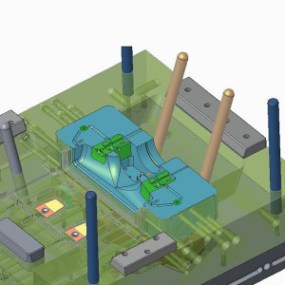

Introduction to Mold Base Design & Injection mold development. making changes in parts to see updates in the mold, while utilizing the latest release of Creo. We help you learn to effectively design using Creo, not read to you from a book, but to understand mold design concepts.

In this course you will be learning the layout and design of Plastic Injection Mold Base. Any changes made to the design model automatically propagate to the mold components and assemblies. We help design engineers learn how to make changes quickly to set them up for becoming experts faster. Participants will learn how to create final extract components that reflect the geometry of the design model, along with shrinkage considerations. As with all Design-Engine classes, participants keep the training material login and password for life.

This Creo Mold Base training course is intended for serious design engineers, tooling engineers, anyone tasked to purchase plastic injection parts, and anyone who wants to become proficient at developing plastic injection mold bases in just one week: OEM Manufacturers, Managers and Molders, Tooling Buyers and Engineers, Product Designers, Toolmakers, Mold Makers, and Junior Mold Designers.

Topics

- Mold Base Layout

- Top-Down Design

- Cooling lines

- Base Steel

- Molding Press and Mold Anatomy

- Mold Types

- Ordering Steel

- Plastic Behavior, Flow

- Components & Functions

- Standards

- Shrinkage

- Cooling

- Venting

- Ejection

- Mold Assembly

- Lift Holes

- Lifting Components

- Machining

- Runners & Gates, GuideLines & Good Practices

- Part and Mold Design from start to finish – a hands on experience

- Generating a complete part design

Duration

40 hours = $3100 per student or 16 hours = $2000 per student

For corporate rates, please call (312)226-8339

Prerequisites

Prior experience with Creo or the 2-day Plastics Part Design class is helpful but not necessary

Projects

- Prepare the mold assembly for commercial components

- Lay out and develop mold bases for various parts supplied by Design-engine or the instructor

- Compound Parting Surface

- IGES / STEP part without the supplied parting surface

- Finishing a complete mold design in 3D CAD

- Creating a core and cavity assembly

- Participants are encouraged to bring their plastic parts in any format for this class

Discussions

- Mold Design set up

- Preparing parts for the manufacturing process

- Deliberate & derive the parting surfaces of IGES / STEP parts

- Nominal wall thickness

- Draft Check and Nominal wall

- Deliberate thin wall design

- Account for Side Action

- Selecting and Importing Standard components & Mold bases

- How Top-down Design facilitates the mold base development process

- Analyzing the part design for mold construction

- How changes made to the design model will automatically propagate to the mold components & assemblies

- How to account for shrinkage

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.