Mastering Creo Sheet Metal Training

Creo Sheetmetal Training Description

Most Designers using the Creo Sheet metal module have years of experience doing the same thing over and over. This course helps your designers expand and master the use of Creo Sheetmetal. Coupled with multi-body and using surfaces plus use a wide variety of tools and workflows made available to Creo over the recent years your team will be more efficient and knowledgeable. Making changes to Creo sheet metal components that are part of an assembly are made and updated parametrically throughout the entire design process. The result is fully associative solid models of sheet metal parts and assemblies ready for production. Participants will be trained to work on items such as small battery contacts, aircraft mounting brackets, electronics enclosures, larger stove/oven components, or auto panels. The curriculum can be combined with Creo Surfacing tools for automobile sheet metal functions or for smaller battery contacts.

Prerequisite: Design Engine’s Learn to Design using Creo Sheetmetal course or consider having your team take the entire 32 or 40 hour version of this course where the last day is focused on organizing company Creo deliverables.

Creo Sheetmetal Training Topics

- Set up Creo Sheet Metal for team design efforts

- Bend allowance and developed length

- Y & K factors

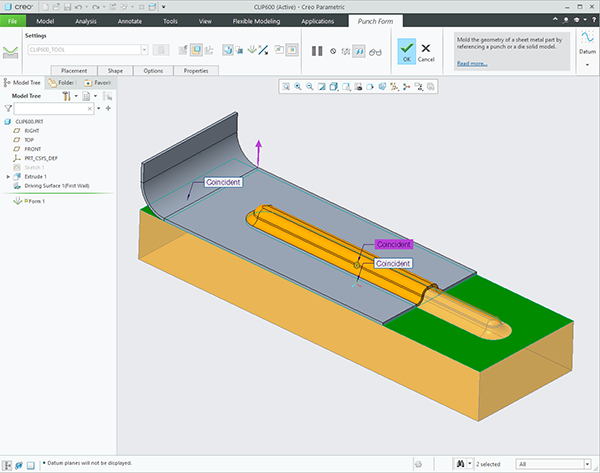

- Punch and die reference parts

- managing reference parts in Windchill

- Sheet metal bend tables

- Deformation areas

- Importing STEP / IGES geometry then creating flattened states from problematic geometry

- Flexible modeling specific to Creo Sheet Metal

- Starting with Solid parts vs Sheet Metal parts, i.e. convert vs conversion

- Alternate methods and workflow for experts

Duration & Cost

16 hours = $1650 per participant

32 hours = $2500 per participant

40 hours = $2900 per participant

Note: This course is the second part of the two learn to design with sheet metal course & can be customized for a full week.

For corporate rates, please call (312)226-8339

Prerequisites

Prior Creo Sheet Metal training or experience is highly recommended. Consider the 32 or 40 hour versions of the Creo sheet metal training course.

Projects

- Various brackets that come together precisely when folded

- Flanged toolbox

- Sheet metal enclosure that puzzles with other sheet metal parts

- Sheet metal components that require precise fit using multi-body

- Fabricated sheet designed for import surfaces

- 1960’s motorcycle Brake Drum lever

- Snap Ring with a pattern that the design requires parallel edges when the pattern is completed

- Hing Brace with form feature for added structural integrity

- Using the Covert function establishes a wide variety of geometry including rear cowling for a YAMAHA seat support

- Also using Creo Covert establish an enclosure for protecting motherboard chips from electro interference.

- Using Blends establishes geometry for the guard rail endcap. Use surfaces effectively to first establish the guard rail then define the geometry of the end cap to manage tolerances to the guard rail

- Wire connector and Other uses of Blend

- Ultrasonic cleaner lid and handle assembly of sheet metal components

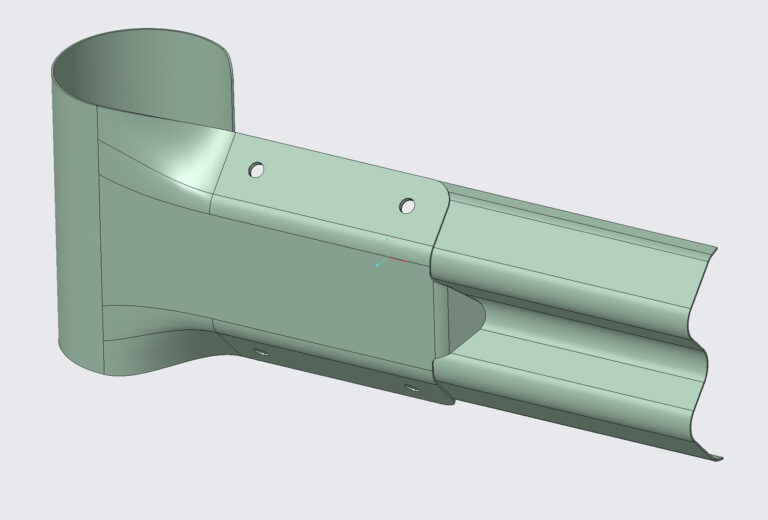

- Hose real arm and assembly where a gusset is established for added strength

- Stover burner *also a form feature

- deep-draw Kohler sink

- Louvers for removing heat from an enclosure

- door latch

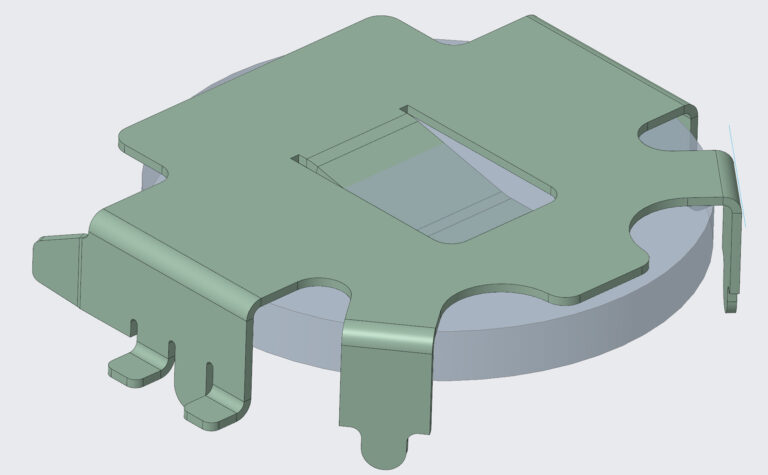

- Retaining clip to snap lithium battery disk

- F250 Brake clip

- Yamaha Oil pickup

- Sheet Metal Lamp made from one sheet

- MÖBS sheet metal fabricated chair

- drawer assembly made of 18 Gage sheet

- E-Stop lockbox with multiple sheet metal parts joggle.

Discussions

- Various manufacturing processes related to Sheet metal fabrication

- Differences between Notch & Punch Forms

- various sheet metal design and manufacturing processes

- Use of geometric tolerance in Creo drawing mode

- Discuss the use of parameters on detailed drawings

- UDF features for speed & efficiency

- Discuss cross-sections and their many forms with respect to detailing

- Adding and modifying Creo detail notes and workflow issues on sheet metal detailed drawings

- Standard drafting notes related to Creo Detailed Drawings

- Discuss various sheet metal techniques with examples of how to handle flat patterns

- Utilize advanced assembly functions such as skeleton parts & top-down design

- Discuss obtaining specific tolerances concerning fabrication and adjusting Y & or K factors in Creo Sheet metal

- Discuss applying various stretching due to deformation grids or areas

- Using import data doctor on STEP or IGES geometry

- import Assemblies as Solid Bodies vs a Creo Assembly

- Converting STEP or IGES imports to legitimate Creo Sheet metal parts for manufacturing

- Flexible modeling tools specifically related to Creo sheet metal imports

- Working with sheet metal vendors and preparing a deliverable to obtain the desired results and tolerances

- When to use flattened states on detailed drawings concerning Sheet metal fabricators, partners vs vendors

- Differences between Vendor & partner manufacturers and do you include flattened state on detailed drawings for vendor/partner?

Video Training Delivery System

Ask your Design Engine account manager about our Training Delivery System(TDS), an easy-to-follow guide for designers and engineers who want a supplement to this course.