An economic slowdown seems increasingly probable and they occur with regular frequency. Fear, resentment, and job layoffs may be unavoidable. Inflation fears, a slowing of qualified designers and engineers who emigrate, stock market fears, and trade wars with neighboring countries and China alike all take the confidence out of upper-level managers propelling fears the economy to worsen. Is the U.S. economy headed for a recession? Stocks have plunged. So have measures of consumer and business confidence. Forecasters expect slower growth, higher unemployment, and faster inflation than they did just a few months ago, and yesterday, policymakers at the Federal Reserve said they agreed.

The question is, what do progressive, forward-thinking organizations do to respond? Companies like J&J, Google, and 3M are often categorized as progressive—how do they adapt in times of uncertainty?

This article or blog post looks into what both organizations and individual designers & engineers can do to navigate economic downturns. Perhaps this should have been separated into two blog posts—one exploring strategies at the corporate level and another focusing on personal approaches. As engineers and designers, we tend to lead management (many times by planting seeds & without them fully realizing our involvement), and in times of economic chaos or uncertainty, we have a lot to offer management. The economy may get bad fast, but how we choose to react may separate product manufacturers from winners and losers.

From the Company perspective: The Product Manufacturer or Design Consultancy

During an economic downturn, forward-thinking companies take strategic measures to stay resilient or ahead of it all. While cost-cutting may be necessary, innovation should not take a back seat. Cost cutting could be felt in layoffs often with the luck of the draw. But what next after the belt is tightened? how many options does HR have to help with staff attitudes? What do we do with the smaller workforce or team and the project goals remain the same? What’s healthy is aiming for long-term growth and resilience to economic downturn. A progressive manufacturing company might play offensive vs less healthy opt for defensive:

-

- Assessment. Take stock and see where you at currently. What recourse needs refreshing, Trading in legacy equipment, or refinancing equipment from your resellers?

- Invest in Research. Investing in research and development is to stay ahead of competitors. This can mean many different things. R&D means investing in activities that drive innovation, leading to the development of new products, processes, and technologies, ultimately improving competitiveness and profitability. This entire blog post is about what this means for driving economies.

- Negotiate. Of course, tariffs are an issue and will be passed on to the consumer. Because they are expensive, consider splitting the cost of tariffs between the parties involved.

- Invest in marketing. Even with a smaller budget, marketing can yield significant returns by increasing brand awareness, driving sales, and fostering customer relationships, making it a strategic investment for business growth.

-

- Invest in the team. Invest in training your design and development team and don’t forget management. At Design Engine we offer a wide variety of classes including sketching for engineers classes to Creo & Solidwroks classes classes.

-

- Encourage brainstorming. Consider brainstorming topics such as new product ideas to how to solve various manufacturing problems or marketing ideas. Brainstorming is a powerful tool if wielded by an experienced leader. Weekly meetings involving both ID & ME teams with the attitude that no idea is a bad idea approach then narrow down those ideas in a separate focused meeting. Design Engine has specific classes that teach engineers how to lead brainstorming sessions called Idea Generation & Facilitation workshops. Other classes for enhancing communication with engineers and their managers https://design-engine.com/design-classes-for-engineers/

-

- Resilient Strategies. Focus on resilient strategies to navigate challenging market conditions. Maybe this involves continuous monitoring of market trends and consumer feedback, allowing businesses to pivot and adjust their approaches in response to changing circumstances. Companies like GWI market research USA data set covers an 80K+ annual sample, representing the views, behaviors, and interests of 250 million US consumers in all 50 States. They can also help with global data sets.

-

- Product Data. Leverage product data for strategic decision-making Consider using companies like Statista https://www.statista.com for help navigating statistical data.

-

- Develop New Markets. Explore new markets and customer segments to diversify their revenue streams. Market research companies can help. Consider organizations such as Ipsos, Nielsen & Kantar Design Engine in the past has partnered with various agencies and made trade deals. We help with 3d modeling for the advertising agency in trade we get help with marketing. In fact, Design Engine established various dragsters for the US ARMY and Marlboro-specific racing graphics & Mustang Vehicles for Leo Burnett the advertising agency for the US ARMY & Marlboro.

-

- Invest in Assets. Take advantage of depressed prices to acquire assets like plants, machinery, and property, which can help them gain a competitive edge after the recession. It’s crucial to prioritize cash flow and avoid overspending based on future growth hopes. Engineering and/or design Firms might consider purchasing used 3d printers or used CNC machines. Tormach CNC machines are cheap enough to go new as opposed to used.

- Going above and beyond is infectious. People are not considered assets however, consider investing in your team can change everything for the better. Quiet quitting” refers to employees disengaging from their roles by doing the bare minimum to maintain their jobs, without formally resigning, often due to feeling undervalued or overworked. These bad attitudes can be hard to place a cost onto yet charges to job numbers can go unchecked. Attitudes can be changed through training, and development can go a long way toward establishing a positive work environment where the team can go above and beyond in their jobs where results will significantly boost performance and engagement, ultimately benefiting the company.

- Invest in Assets. Take advantage of depressed prices to acquire assets like plants, machinery, and property, which can help them gain a competitive edge after the recession. It’s crucial to prioritize cash flow and avoid overspending based on future growth hopes. Engineering and/or design Firms might consider purchasing used 3d printers or used CNC machines. Tormach CNC machines are cheap enough to go new as opposed to used.

-

- Focus on Customer Needs. Stay closely connected to customer needs to ensure their products and services remain relevant and valuable.

-

- Leverage Relationships. Strengthen relationships with suppliers, customers, and other stakeholders to build resilience and create opportunities.

-

- Identify Opportunities. To foster creative solutions, conduct a 15-minute brainstorming session with marketing, engineering, and industrial design teams. Management needs to be involved as well. Meetings require first emphasizing that all ideas are welcome and no idea is a bad idea. A later meeting can narrow down the proposed ideas into an actionable items list.

- Focus on agility and adaptability. Change is the only constant.

- using consultancies. Product manufacturing companies can leverage contractors from Belcan or Tad technical and/or external product design consultancies to navigate both peak workloads and downturns. Innovation teams can bring in specialized expertise from firms like Smart Design, Design Engine product development, or Teams Design without expanding their full-time staff. These external teams often provide the necessary skills and speed to drive success where in-house resources may be limited.

- Identify Opportunities. To foster creative solutions, conduct a 15-minute brainstorming session with marketing, engineering, and industrial design teams. Management needs to be involved as well. Meetings require first emphasizing that all ideas are welcome and no idea is a bad idea. A later meeting can narrow down the proposed ideas into an actionable items list.

-

- Strategic Opportunities. Actively look for opportunities that arise during the downturn, such as acquiring competitors or expanding into new areas. Management doesn’t always listen however in many cases strategy wins. Lifetime Products, the largest plastic processing manufacturer in the United States, based in Utah, saw an opportunity during a brainstorming session between industrial designers, engineers, and management. By leveraging their strong retailer relationships and manufacturing expertise in roto-molding, they entered the kayak market and quickly dominated—growing it by 4X.

- Strategic Opportunities. Actively look for opportunities that arise during the downturn, such as acquiring competitors or expanding into new areas. Management doesn’t always listen however in many cases strategy wins. Lifetime Products, the largest plastic processing manufacturer in the United States, based in Utah, saw an opportunity during a brainstorming session between industrial designers, engineers, and management. By leveraging their strong retailer relationships and manufacturing expertise in roto-molding, they entered the kayak market and quickly dominated—growing it by 4X.

For the Individual: Industrial Designers & Engineers

As Warren Buffett says, generally speaking, investing in yourself is the best thing you can do. Designers and engineers play a critical role in shaping a company’s future, especially during economic uncertainty, but sometimes upper-level management will not listen or their hands may be tied. If management is smart they will stay fixed to the R&D team’s ideas. To stay competitive designers and engineers have the ear of management as well. Designers and Engineers can invest in themselves.

-

- Assessment. Always start with a serious assessment to evaluate where you are currently. Asses your individual skills or identifying possible gaps in your knowledge base could be useful.

- Strengthen your portfolio. Engineers can have portfolios also. Contact Design Engine, it might be we can help.

- Assessment. Always start with a serious assessment to evaluate where you are currently. Asses your individual skills or identifying possible gaps in your knowledge base could be useful.

-

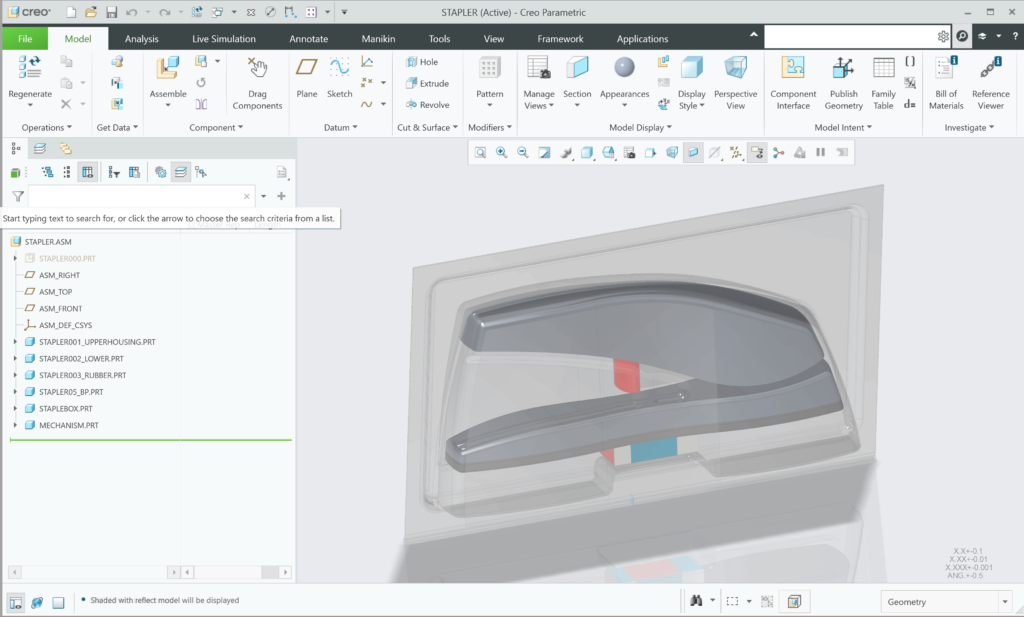

- Learn a New Design Tool. Consider learning a completely different software package as much can be learned about workflow and design approaches. Continued learning keeps us nimble and quick and helps our attitudes.

-

- Visit trade shows. There is a vast knowledge to be had by visiting trade shows. For industrial Designers, it’s imperative for you to stay ahead of trends. Come back with a report or presentation to the collective team in that way your company may pay for the trip. In the past design engine team would visit the Milan Furniture Design Fair or the 100 Percent Design Show in London.

-

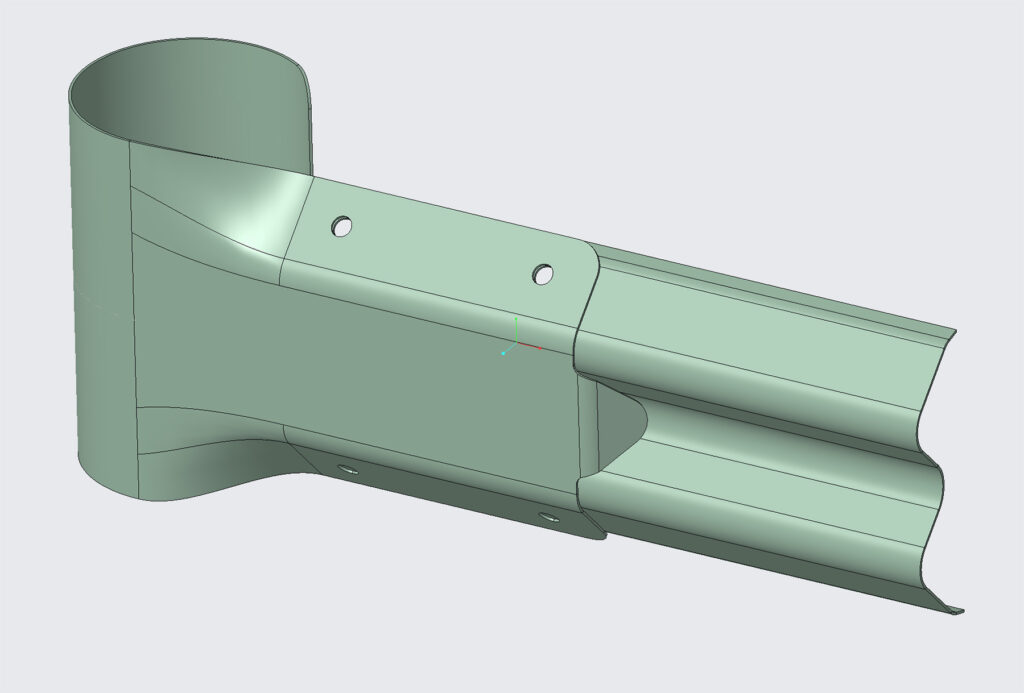

- Learn a new tool within your current CAD package. learning is the key to happiness. Also consider learning advanced modules in their current software not just learning a new tool like Creo or Solidworks but pushing yourself with Creo surfacing training, Creo or Solidworks Sheet metal training. Or training that is manufacturing-oriented like plastic part design or die casting training, Creo Simulate, Creo Cabling, or Creo generative design. Become the company expert in Manufacturing. If PTC or Creo Value-added resellers will not let your team have a 30 or 90-day license consider using the slightly limited version of Fusion 360 for experimentation.

-

- Explore AI-driven 3D modeling and brainstorming tools. Assign team members to the research team. Have them share with others what they have learned. In that way, they see you as the expert. After all, we never tell others we are the expert.

-

- Align your expertise. Evolving industry needs can become apparent during a downturn. Listen to the team and remain ahead of trends. Stay fresh. As we age we tend to become set in our ways. Remaining informed with the new trends dispels how others think of us. Consider traveling to the tradeshows. Design Engine always went to the Chicago Housewares or the Furniture fairs.

-

- Gaining additional skills. For instance, if you’re trained in PTC Creo, consider learning SolidWorks 3D CAD. It may double your opportunities if you need to look for new or additional work. If you use Solidworks at work, consider learning Creo as it will double your opportunities job-wise. You might also consider sketching for engineers or learning how to lead a brainstorming session. Links to those classes are below.

The Strategic Role of Product Innovation

Economic downturns could sharpen business leadership’s focus as well. As stakes rise, companies prioritize investments that drive long-term success rather than short-term sales boosts. While increasing revenue through aggressive sales efforts may offer temporary relief, investing in product innovation ensures a lasting impact.

Historically, companies that invest in R&D during downturns emerge stronger. A company’s product is no longer just about its core functionality—it serves as a primary channel for sales, marketing, and customer engagement. Moreover, product data provides valuable insights, helping businesses make informed strategic and tactical decisions.

Upskilling. From the R&D perspective training can ensure a new level of success as training new skills is paramount during downturns. Creo training or Solidworks training of course but sketching classes for engineers or teaching your engineers how to lead brainstorming sessions. Design Engine classes can be team-building or competitive-oriented also. Management might consider Generative design as a group exercise.

For example, leveraging product analytics can reveal which customers are at risk of churning and need additional support, influencing retention strategies. A data-driven approach is transforming how organizations view product management, positioning it as a key driver of business resilience.

The Bottom Line

Companies that recognize the vital role of product innovation will not only survive economic downturns but thrive. Coming out stronger better smarter is a dream that can be accomplished. Of course, training is part of this puzzle as investing in the people engine is paramount. The businesses that emerge strongest will be those that see their products as more than just offerings, they will view them as strategic assets that fuel growth. Customer loyalty and employee loyalty add to long-term success.

-

- Long-Term Growth:

By investing in Designers & Engineers. Focus on innovation and growth through brainstorming with complete teams of ID, ME, and management together. Progressive companies are better positioned to capitalize on the recovery and emerge stronger than their competitors.

- Long-Term Growth:

-

- Resilience:

Their focus on efficiency and cost control helps them weather the downturn and survive when others struggle.

- Resilience:

-

- Competitive Advantage:

By investing in assets, robotics, and people, + developing new products, and listening to your team, progressive companies can gain a competitive advantage that will last long after the recession ends.

- Competitive Advantage:

After all, it’s industrial designers and engineers, by create products and company leadership that are the primary drivers of trends. Working on innovative design and development teams is the most impactful way to lead out of a recession. product designers are the developers who put products in front of trendsetters pushing the early adopter.

Bart Brejcha leads teams of designers and engineers plus teaches a wide variety of classes all @ Design Engine. bart at designengine.com

Creo Training

CREO TRAINING: LEARN TO DESIGN

Creo Update Training

Creo Advanced Modeling

Creo Surfacing Training Courses

Cable Harness Design & Creo Schematics WEEK ONE

Creo Piping & Schematics

Solidworks Training

SOLIDWORKS Training Courses

SOLIDWORKS Training: Learn to design

Solidworks Surfacing Training: WEEK ONE

Manufacturing Training

Manufacturing Week Long Comprehensive Workshop

Plastic Part Design for Injection Molding

Forge Training

Die Cast Part Design Intensive

GD&T Training